Forged Pipe Union | Threaded & Socket Weld Forged Unions | ASME B16.11 Standard

Release Time:

Jul 28,2025

High-performance Forged Unions in threaded and socket weld types, compliant with ASME B16.11 and MSS SP-83. Ideal for high-pressure, small-bore piping systems in oil, gas, chemical, and steam applications. Available in carbon steel, stainless steel, and alloy materials.

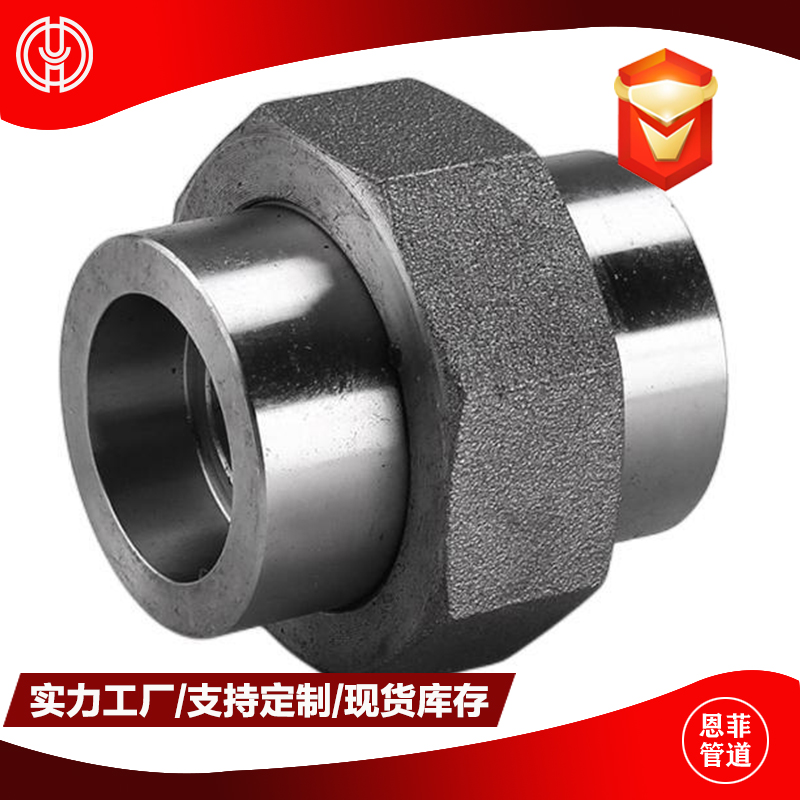

FORGED FITTINGS – UNION

Structural Features:

A Forged Union is a three-piece fitting designed to connect two pipes and allow quick disconnection without causing deformation or requiring rotation of the piping.

It consists of:

A male end

A female end

A central nut that holds the two ends together via threaded or socket weld connection

Forged unions offer excellent strength, easy maintenance, and are ideal for frequent dismantling or realignment of pipelines.

Connection Types:

Threaded Union (THD) – NPT/BSPT threading

Socket Weld Union (SW) – Welded with high integrity

Both types ensure tight sealing and pressure resistance

Standards:

ASME B16.11

MSS SP-83 – Forged steel unions

BS 3799 (optional)

Pressure Ratings:

Class 2000 / 3000 / 6000

Designed for high-pressure piping systems where ease of connection and disassembly is essential

Applications:

Forged unions are ideal for systems requiring:

Frequent assembly/disassembly

Easy maintenance access

Precise pipe alignment

Commonly used in:

Instrumentation lines

Oil & Gas piping

Chemical process units

Steam lines

Water treatment systems

Common Materials:

Carbon Steel (ASTM A105)

Stainless Steel (ASTM A182 F304/F316)

Alloy Steel (ASTM A182 F11/F22)

Also available in Duplex, Monel, Inconel, and other special alloys

Recommendation:

Forged Unions are indispensable in high-pressure small-bore systems requiring reliable yet removable connections.

They are particularly suitable where regular pipe maintenance, testing, or section replacement is required.

With high mechanical integrity and tight sealing, unions improve the efficiency and flexibility of piping systems.

Key words:

Other News