PLATE FLANGE: The Cost-Effective Solution for Low-Pressure Piping

Release Time:

Jul 21,2025

Lightweight, easy to install, and ideal for non-critical systems like water supply, HVAC, and general industrial pipelines.

PLATE FLANGE

Structural Features:

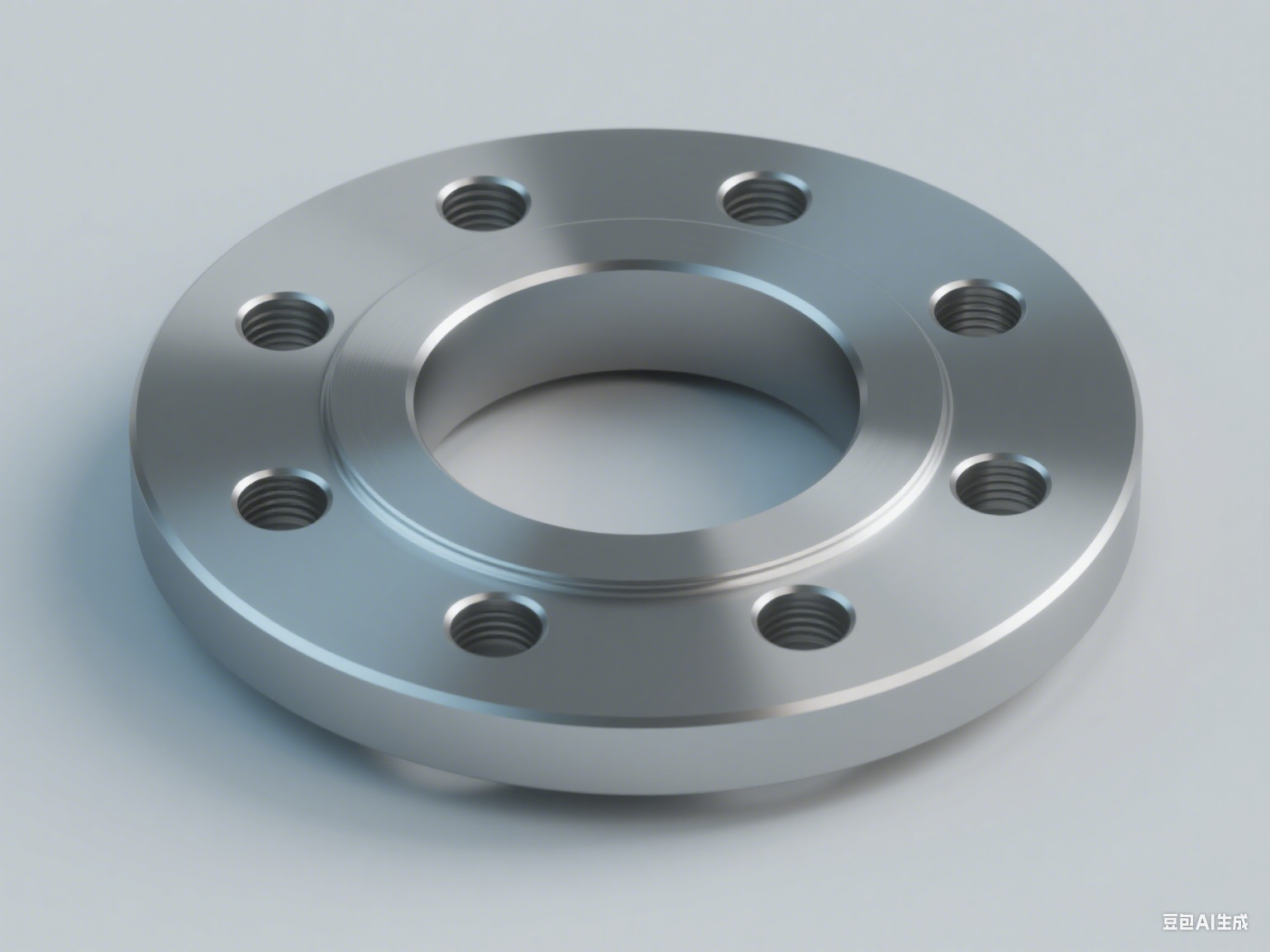

A flat, circular flange without a neck, typically made from a single steel plate.

Designed for simple, low-pressure piping systems.

The flange has bolt holes and a center opening for the pipe to pass through.

Its flat profile makes it economical, lightweight, and easy to install.

Welding Method:

Connected by fillet welding around the pipe at the flange’s bore.

Welding is done only on the outside (and optionally inside) of the flange.

Does not require beveling or complex alignment, suitable for non-critical connections.

Applications:

Ideal for:

Low-pressure, non-hazardous pipelines

Water supply systems

HVAC ducting

General industrial piping where cost-efficiency is key

Common in:

Building infrastructure

Light-duty waterworks

Low-pressure gas systems

Common Size Standards:

Custom sizes available

Often manufactured to EN1092-1 (Type 01), DIN 2576, or ASME dimensional equivalents

Pressure Ratings:

Generally used in Class 150, or PN6 / PN10 / PN16 systems

(Not recommended for high-pressure or high-temperature applications)

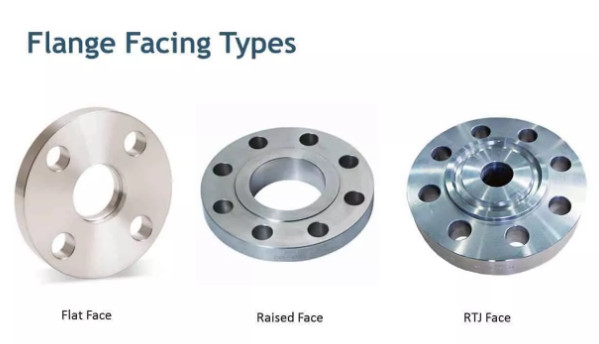

Flange Face Types:

FF (Flat Face) – most common

Also available with custom grooves for specific sealing needs

Materials:

Carbon Steel (most common), Stainless Steel, Mild Steel, Galvanized Steel

Recommendation:

Plate flanges are a cost-effective and simple solution for non-critical or low-pressure connections.

They are especially suitable for budget-conscious projects and systems that do not demand high structural performance.

Recommended for basic utility piping where ease of fabrication and installation is more important than strength.

Key words:

Other News