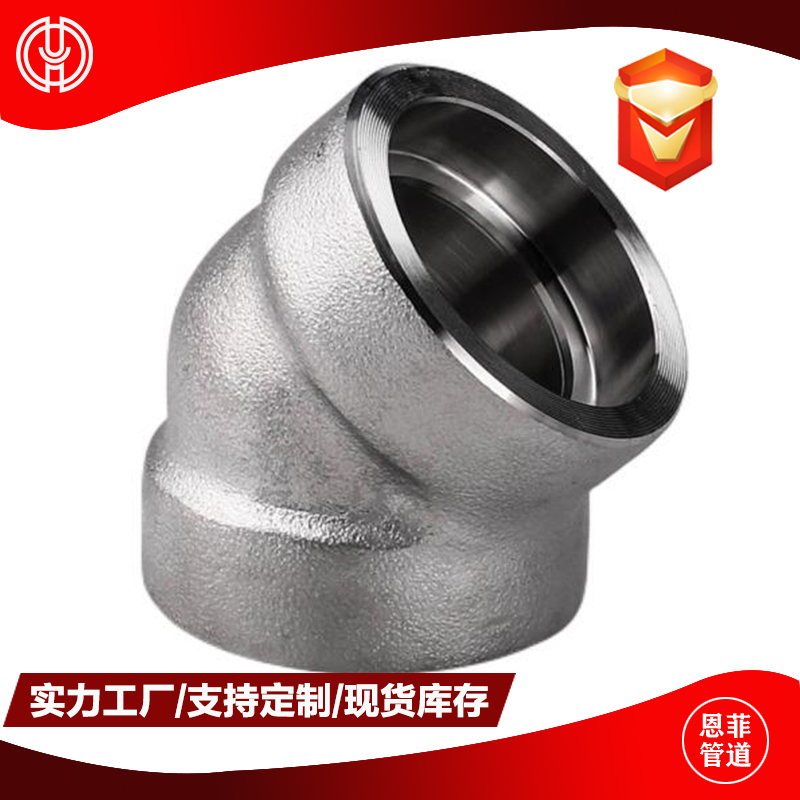

High-Performance Forged Elbows for High-Pressure Piping Systems

Release Time:

Jul 23,2025

Compact, Durable, and Reliable – Ideal for Oil & Gas, Power, and Industrial Applications

FORGED FITTINGS – ELBOW

Structural Features:

Forged elbows are high-strength pipe fittings used to change the direction of flow in a piping system, typically by 45° or 90°.

Manufactured from high-pressure forged round bars or billets, ensuring exceptional strength, durability, and compact size.

Designed for use in small diameter, high-pressure systems.

Types of Elbows:

-90° Elbow: Makes a right-angle turn in the piping

-45° Elbow: Creates a smoother directional change

-Street Elbow: One end is male-threaded, the other is female

Available in socket weld and threaded (NPT/BSPT) connection ends

Standards:

ASME B16.11 – Forged Fittings

MSS SP-79 / SP-83 / SP-95

BS 3799 (British Standard, optional)

Pressure Classes:

Class 2000 / 3000 / 6000 / 9000

(Suitable for high-pressure and high-temperature systems)

Applications:

Widely used in:

Oil & Gas transmission lines

Petrochemical & Chemical plants

Power stations

Shipbuilding and offshore

Boiler and pressure vessel systems

Ideal for tight spaces where large-radius elbows are not feasible.

Common Materials:

Carbon Steel (ASTM A105)

Stainless Steel (ASTM A182 F304, F316, etc.)

Alloy Steel (ASTM A182 F11, F22)

Duplex Stainless Steel / Inconel / Monel / Hastelloy, etc. (for corrosive services)

Connection Types:

Socket Weld (SW): For welded joints, leak-tight

Threaded (THD): For screw-type piping connections (NPT/BSPT)

Recommendation:

Forged elbows are essential in systems requiring compact, durable, and leak-proof directional changes.

They are especially favored in high-pressure applications and environments where reliability and strength are critical.

Recommended over cast fittings when mechanical integrity and corrosion resistance are top priorities.

Other News