Lap Joint Flange: Flexible, Cost-Efficient, and Maintenance-Friendly Piping Solution

Release Time:

Jul 22,2025

Ideal for corrosive environments and systems requiring frequent disassembly — combining precise alignment with material efficiency.

LAP JOINT FLANGE

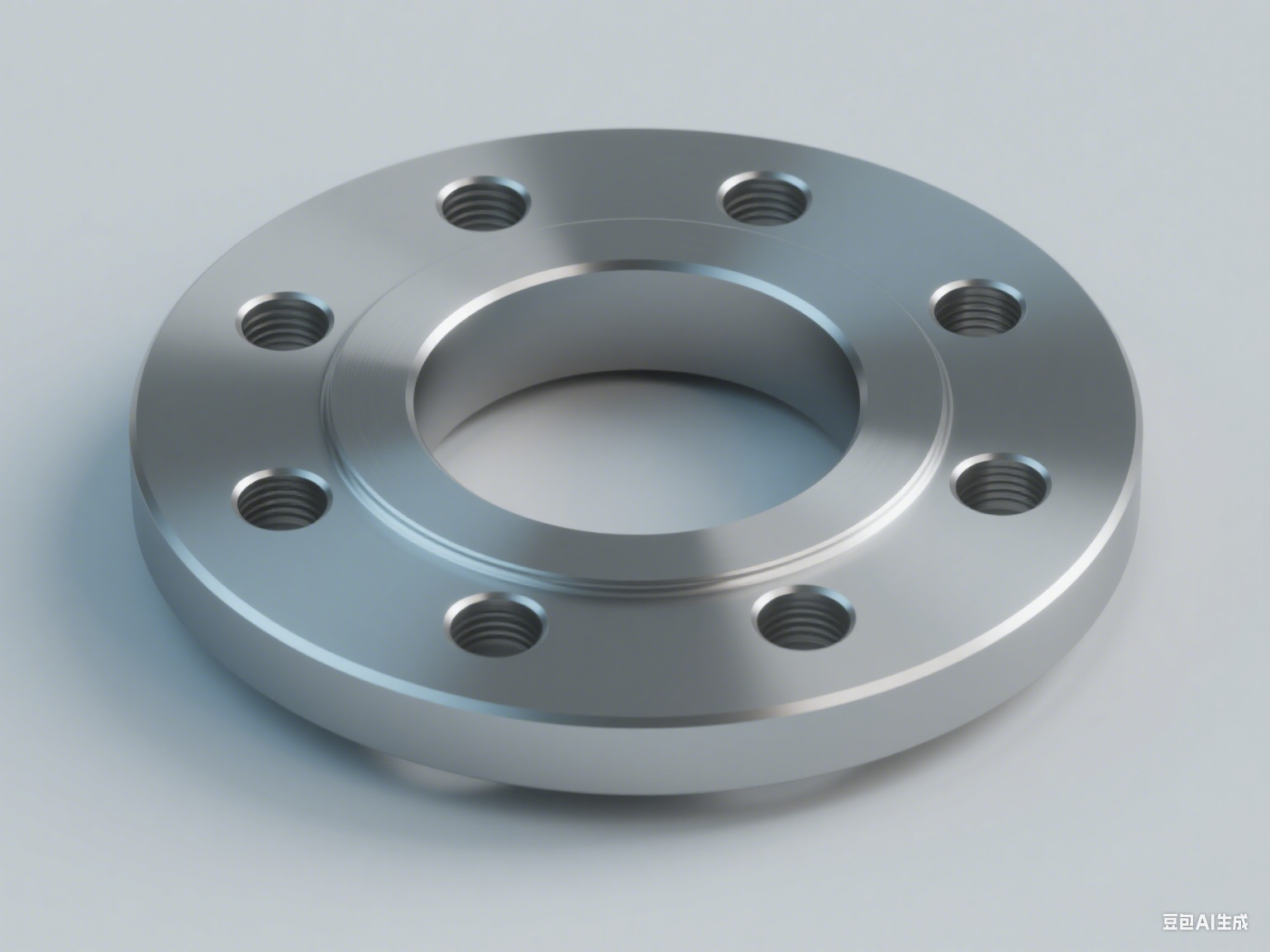

Structural Features:

A two-piece flange system consisting of:

A Lap Joint Flange (loose backing flange)

A Stub End, which is butt welded to the pipe

The flange itself does not contact the fluid directly—only the stub end does.

The flange can rotate freely around the pipe, allowing for easy bolt alignment, especially in tight or hard-to-reach spaces.

Welding Method:

Only the stub end is welded to the pipe using butt weld.

The lap joint flange remains loose, sliding over the pipe.

This allows for quick disassembly, alignment, and maintenance.

Applications:

Ideal for:

Frequent dismantling of pipelines

Corrosive media pipelines (flange made from carbon steel, stub end from corrosion-resistant alloy)

Systems requiring easy alignment and maintenance

Common in:

Chemical industry

Food & Beverage processing

Pharmaceutical plants

Water treatment systems

Offshore and marine piping

Common Size Standards:

ASME B16.5 (½”–24”)

ASME B16.47 (Above 24”)

Stub ends are made to ASME B16.9 standards

Pressure Ratings:

-Class 150, 300, 600, 900, 1500

(Not commonly used in Class 2500 applications)

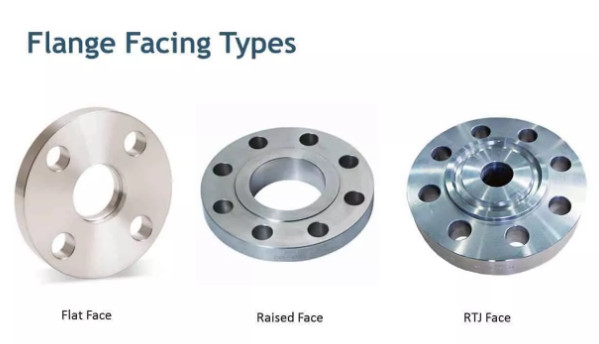

Flange Face Types:

-FF (Flat Face) is most common

-RF (Raised Face) is less common but available

Materials:

-Flange: Carbon Steel, Stainless Steel

Stub End: Stainless Steel, Alloy Steel, Duplex, etc.

(Materials can be mixed for cost-efficiency and corrosion resistance)

Recommendation:

Lap joint flanges are ideal for systems where frequent disassembly, precise alignment, or corrosion resistance is needed.

They are especially effective in environments where material cost and maintenance accessibility must be balanced.

Highly recommended in chemical, food-grade, or marine piping systems.

Key words:

Other News