GET IN TOUCH WITH NFI STEEL

Jacketed Flanges Reducing Flanges SH/T3426 HG/T20615

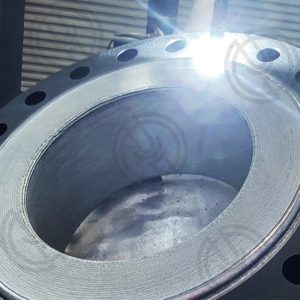

Jacketed Flanges are a specialty flange that are most often used on projects that require the fitting together of different sized pipes,Jacket Flange has two different welded pipes, so it is also called Reducing Flanges.

Jacketed Flanges in Petrochemical Industry-Reducing Flanges SH/T3426 HG/T20615

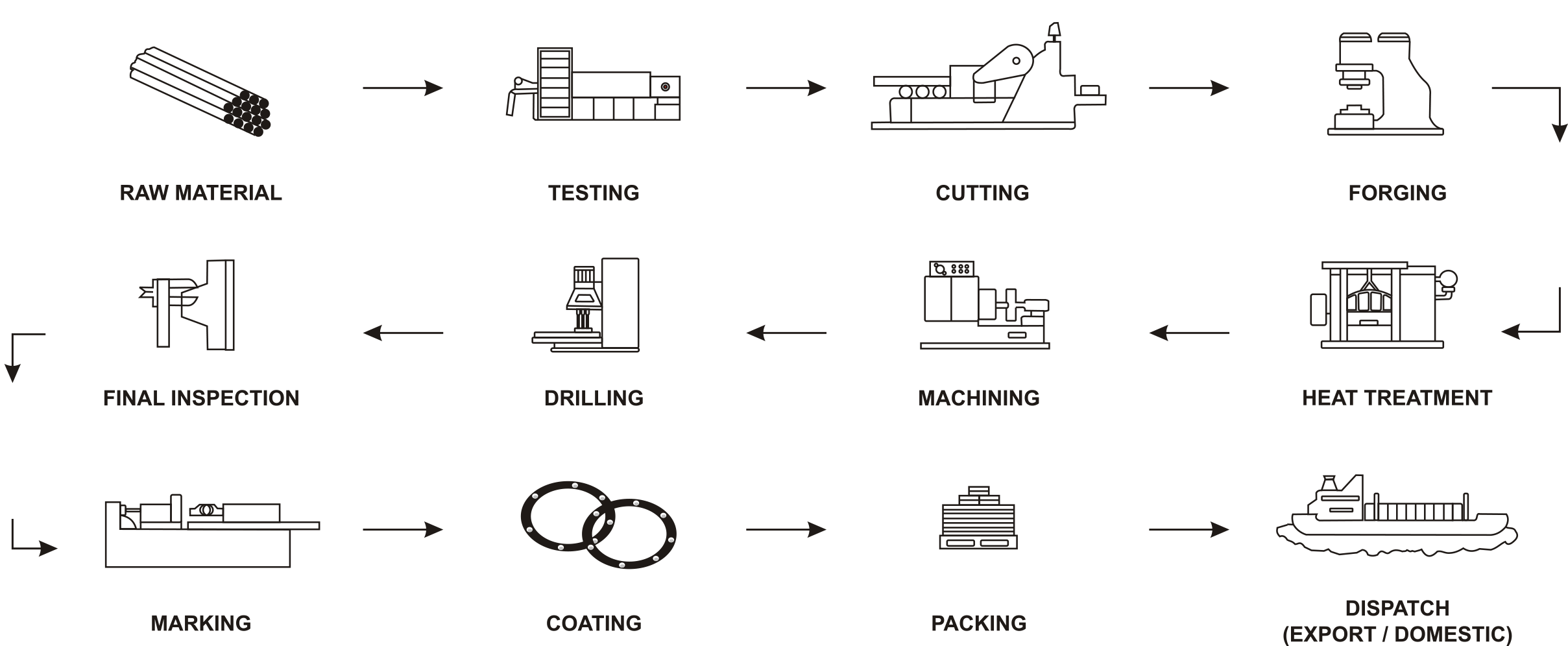

Cangzhou Enfei Pipeline Equipment Co., Ltd. is an excellent manufacturer of jacketed flanges in China. The jacketed reducing flanges are forged from raw metal round steel or steel plates under high temperature and pressure. Therefore, jacketed flanges have high requirements on raw materials. The high quality of raw materials determines the quality of jacketed flanges products.

Next, the performance of the jacketed flanges is determined by the heat treatment process. The heat treatment temperature is usually between 700 and 1300 degrees Celsius. The heat treatment process determines the standard parameters such as low temperature impact resistance, high temperature resistance, corrosion resistance, welding performance and hardness.

Cangzhou Enfei Pipeline Equipment Co., Ltd. is an excellent manufacturer of jacketed variable diameter flanges, using the raw materials produced by the best factories in China, including Yongxing Special Steel, AVIC Shangda, Huaxin Lihua, Qingtuo Group, Laiwu Steel, Valin Steel, Taiyuan Steel, Shanghai Baosteel, Baosteel and other China’s best steel groups. The above raw material manufacturers have been certified by ABS and DNV GL, BV, LR, CCS, NKclass, KR, RINA and RS classification societies. The classification society can issue EN10204 3.2 and EN10204 3.1 bill of materials certificates.

Cangzhou Enfei Pipeline Equipment Co., Ltd. focuses on serving global customers. Manufacturing standards include: SH/T3426, HG/T20615 and customized drawings. Jacketed flanges products produced by Cangzhou Enfei Pipeline Equipment Co., Ltd. have a variety of materials for selection, including ASTM A105, ASTM A182 F11 CL1 Cl2 F11 CL3 CL1 F12 Cl2 F304 F304H F30L F317 F321 F347 F51 F55 F60 ASTM A694 F42 F48 F52 F56 F60 F65 F70, ASTM/ASME SB466 UNS NO. C70600 (Cu/NI-90/10), C71500 (Cu/NI-70/30) ASTM/ASME SB336, ASME SB564/160/163/472, UNS2200 (nickname 200) UNS2201 (nickname 201), UNS4400 (MONEL400), UNS8020 (alloy 20/20 CB3), UNS8825 Inconel (825), UNS6600 (Inconel 600), UNS6601 (inconel 200) 601), UNS6625 (Inconel 625), UNS10276 (Hastelloy C276), etc.

Among the above production materials for jacketed reducing flanges, our dual phase steel meets the requirements of A182 F53/F55 PREN (% Cr+3.3% Mo+16% N) ≥ 40, F51/F60 N=0.14-0.2% and PREN (% Cr+3.3% Mo+16% N) ≥ 34, product pressure 150LB 300LB, product specification 1/2-16 inch, to meet customers’ various choices. Due to the high standards, high-quality materials and various specifications of jacketed flanges provided by our company, we can undertake many small, medium and large projects.

In addition, our firm customer service attitude also enables our customers to obtain high returns. The contracts signed and delivered come from Europe, Africa, Asia, South America, North America and other places. The customers cover a wide range and have won unanimous praise from customers. Our company is also constantly improving its products to adapt to the rapid development of the times and new problems raised in the new era.

Industrial steel flange test certificate: products provided by Cangzhou ENFI Pipeline Equipment Co., Ltd. are also inspected by a third party. The inspection organization can be designated by the customer, and the TPI for dynamic forging and accessories can be arranged by world famous organizations (such as Bureau of International Inspection, ABS, NKClass, SGS, etc.).

Jacketed Flanges Specification

| Size | 1/2〞(DN15)to 60〞(DN1500) | |||||

| Class | 150LBS,300LBS,400LBS,600LBS,900LBS,1500LBS,2500LBS.

DIN Standard PN-2.5,6,10,16,25,40,50,64,110,150,250,320,400. |

|||||

| Flange Face Type | Amerrican Series:Flat face(FF),Raised Face(RF),Tongue(T),Groove(G),Female(F),Male(M),Ring Joints Face(RJ) | |||||

| Surface Treatment | Antirust Paint,Oil Black Paint,Yellow Transparent,Zinc Plated,Cold and Hot Dip Galvanized | |||||

| Manufacturing process | Cutting,Heat treatment,Die Forging/Free Forging,CNC Machining | |||||

| Manufacturing Standards | ANSI/ASME B16.5 Flanges,ANSI/ASME B16.47 Flanges,ANSI/ASME B16.36 Flanges,ANSI/ASME B16.48 Flanges ,MSS SP44 Flanges,ASA,API-605 Flanges,AWWA Flanges,Custom Drawings Flanges ,EEMUA145 146 234 Flanges,BS 10 Flanges,DIN Flanges,EN 1092-1 Flanges,BS 4504 Flanges,JIS Standard Flanges | |||||

Material Grades

| Carbon Steel | ASTM A105/A105N, A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, A694 F42, F46, F48, F50, F52, F56, F60, F65, F70, A516.60, 65, 70 (Spectacle Blind Flange, Spacer Ring/Spade Flange), Steel RST37.2, C22.8 | |||||

| Stainless Steel | ASTM A182 F202, F304/304L/304H, F316/316L, F316H, F316TI, F310, F321, F904L | |||||

| Duplex & Super Duplex Steel | ASTM / ASME A/SA 182 F44, F45, F51, F53, F55, F60, F61, 2205 (UNS No. S31803), 2507 (UNS No.S32750),1.4462,1.4410,1.4547 | |||||

| Alloy Steel | ASTM A182 F1, F5, F9, F11, F22, F91 | |||||

| Copper Alloy Steel | UNS No. C10100, 10200, 10300, 10800, 12000, 12200, 70600, 71500, UNS No. C70600 (Cu -Ni- 90/10), C71500 (Cu -Ni- 70/30) | |||||

| Nickel Alloy | Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II). | |||||

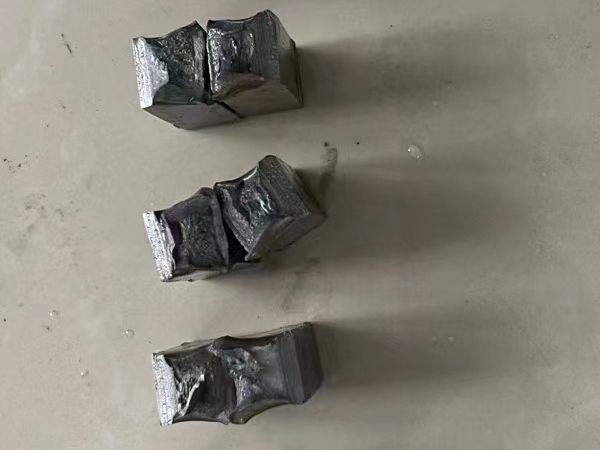

Jacketed Reducing Flanges Tensile Properties Testing

Related products

-

FLANGE

Stainless Steel Flanges A182 F304L F316L Welding Neck Flange

Rated 0 out of 5$1.00Original price was: $1.00.$1.00Current price is: $1.00. Add to cart