GET IN TOUCH WITH NFI STEEL

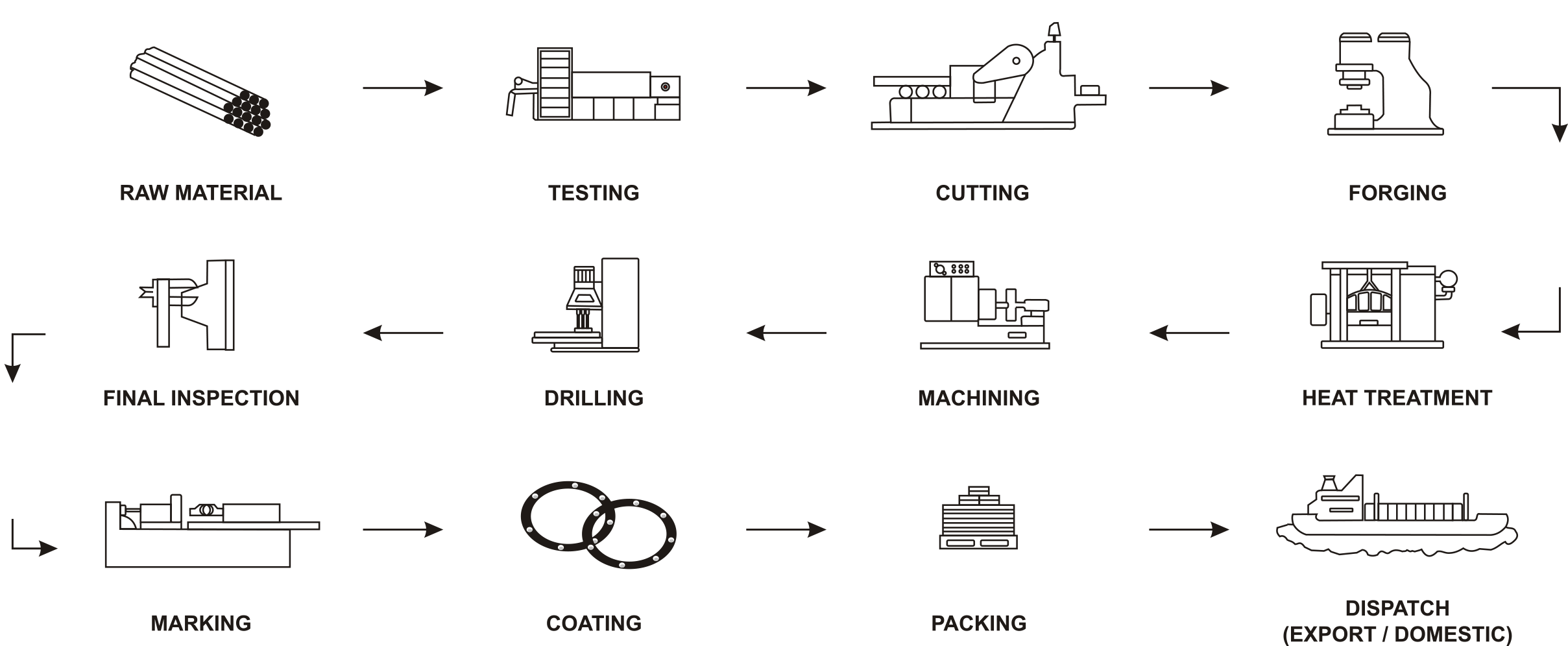

Composite Flange Surfacing Forming-ASME B16.5 Flange

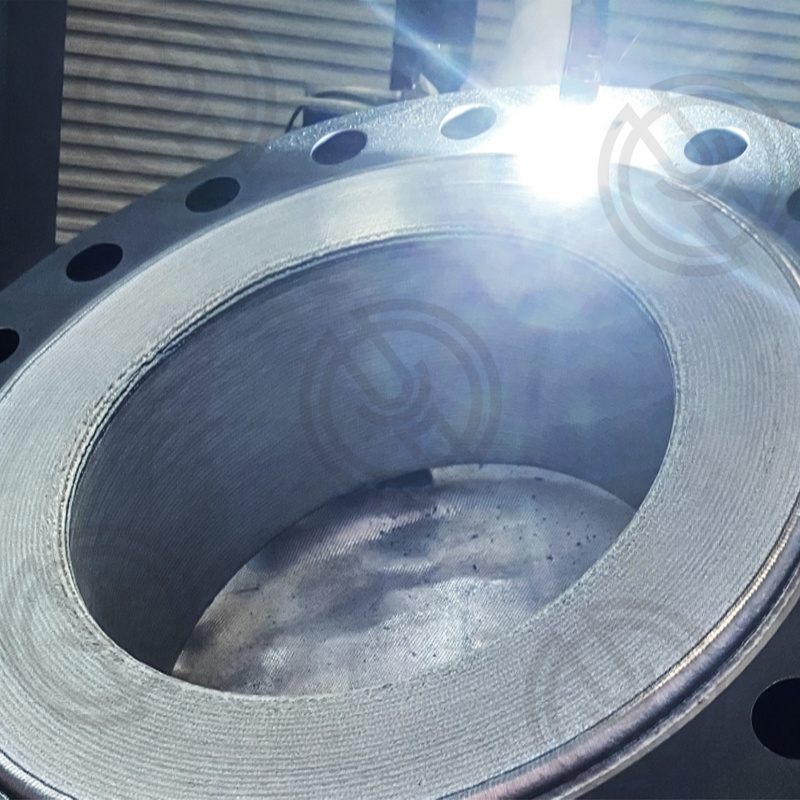

Molding Process of Composite flange -surfacing forming is The inner wall of flange is overlayed by horizontal welding machine,the cladding layer of composite flange mainly includes ER309L, ER385, ER2209 and ERNiCrMo-3.

Stainless steel, nickel base alloy, copper nickel alloy-Composite flange (surfacing forming)

Cangzhou Enfei Pipe Equipment Co., Ltd. is an excellent Composite Flange -Surfacing Forming manufacturer in China.

The Composite Flange -Surfacing Forming is a product formed by high-temperature and high-pressure forging of the raw material metal round bar or steel plate.

Therefore, the Surfacing Forming Flange has high requirements for raw materials.

Surfacing Forming Flange Manufacturer, Supplier, Stockholder in China.

▶What is Surfacing Forming Flange

▶Standard Specification For Surfacing Forming Flange Inconel 625

▶Types Of Surfacing Forming Flange NO6625

▶Surfacing Forming Welding Neck Flange

▶Surfacing Forming Socket Weld Flange

▶Surfacing Forming Slip On Flange

▶Surfacing Forming Blind Flange

▶Surfacing Forming Threaded Flange

▶Surfacing Forming Lap Joint Flange

▶Surfacing Forming Long Neck Weld Flanges

▶Surfacing Forming Orifice Flanges

▶Surfacing Forming Spectacle Blind Flanges

▶Surfacing Forming Swivel Flange

▶Surfacing Forming Jacketed Flanges

Whether the raw materials are high-quality determines the quality of the Surfacing Forming Flange products.

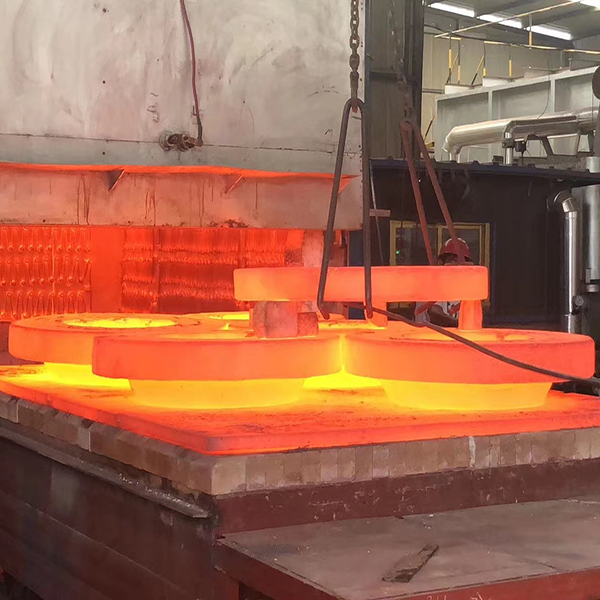

Next, the Surfacing Forming Flange performance is determined by the heat treatment process.

The heat treatment temperature is generally between 700 and 1300 degrees Celsius.

The heat treatment process determines the low-temperature impact resistance, high-temperature resistance, corrosion resistance Standard parameters such as welding performance and hardness.

As an excellent Composite Flange -Surfacing Forming manufacturer.

Cangzhou Enfei Pipe Equipment Co., Ltd. selects raw materials produced by the best factories in China.

Including Yongxing special steel, AVIC Shangda, Huaxin Lihua, qingtuo group, Laiwu Iron and steel, Valin Iron and steel, Taiyuan Iron and steel, Shanghai Baosteel, Baosteel and other China’s best steel groups.

The above raw material manufacturers have passed ABS and DNV GL, BV, LR, CCS, NKclass, KR, RINA and RS classification societies can issue EN10204 3.2 and EN10204 3.1 material list certificates.

Cangzhou Enfei Pipe Equipment Co., Ltd. focuses on serving global customers. Manufacturing standards include: ASME B16.5/ ASME B16.47/ ASME B16.48/ API 17D/ API 6A, etc.

Surfacing Forming Flange products produced by Cangzhou Enfei Pipe Equipment Co., Ltd. have a variety of materials to choose from.

Including:Base metal-CS/LTCS/Low alloy steel Weld Overlay-Ni-base alloy, Stainless steel, Duplex steel, Super duplex steel,Cobalt-base alloy(STL.21#), Copper-base alloy(ERCuNi), etc.

Product pressure 75LB 150LB 300LB 400LB 600LB 900LB 1500LB 2500LB DIN Standard PN-2.5,6,10,16,25,40,50,64,110,150,250,320,400, and product specification 1/8-72 inch to meet customers’ various choices.

Due to the high standard, good material and many specifications of Surfacing Forming Flange provided by our company, we are able to undertake many small, medium and large projects, coupled with our service attitude of resolutely considering for customers, which also makes our customers have a high rate of return.

The contracts signed and delivered come from Europe, Africa, Asia, South America, North America, etc., with a wide range of customer coverage, and have won the unanimous praise of customers.

Our company also keeps refining its products to meet the new issues raised in the new era while the rapid development of the times.

Industrial Surfacing Forming Flange Test Certificates: Cangzhou Enfei Pipe Equipment Co., Ltd. offer its Products with Third Party Inspection also.

The Inspection Agency can be nominated by clients or Dynamic Forge & Fittings can be arrange the TPI by World reputed Agencies like Bureau Veritas, ABS, NKClass,SGS and many other.

Surfacing Forming Flange Specification

| Size | 1/2〞(DN15)to 60〞(DN1500) | |||||

| Class | 150LBS,300LBS,400LBS,600LBS,900LBS,1500LBS,2500LBS. | |||||

| Flange Face Type | Amerrican Series:Flat face(FF),Raised Face(RF),Tongue(T),Groove(G)

Female(F),Male(M),Ring Joints Face(RJ) |

|||||

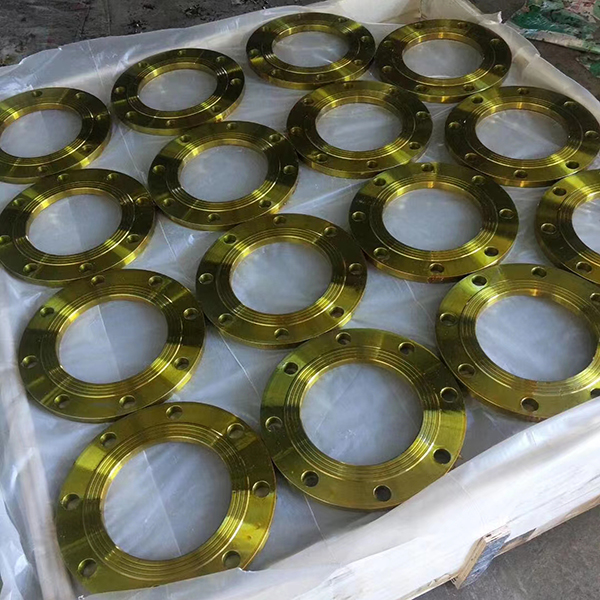

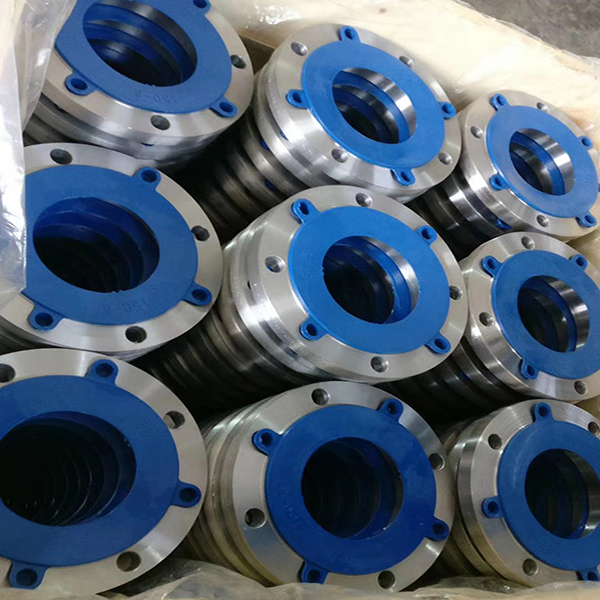

| Surface Treatment | Antirust Paint,Oil Black Paint,Yellow Transparent,Zinc Plated,Cold and Hot Dip Galvanized | |||||

| Manufacturing process | Surfacing Forming | |||||

| Manufacturing Standards | ASME B16.5/ ASME B16.47/ ASME B16.48/ API 17D/ API 6A | |||||

| Base metal | CS/LTCS/Low alloy steel | |||||

| Weld Overlay | Ni-base alloy, Stainless steel, Duplex steel, Super duplex steel. Cobalt-base alloy(STL.21#), Copper-base alloy(ERCuNi) |

|||||

Surfacing Forming Flange mechanical welding

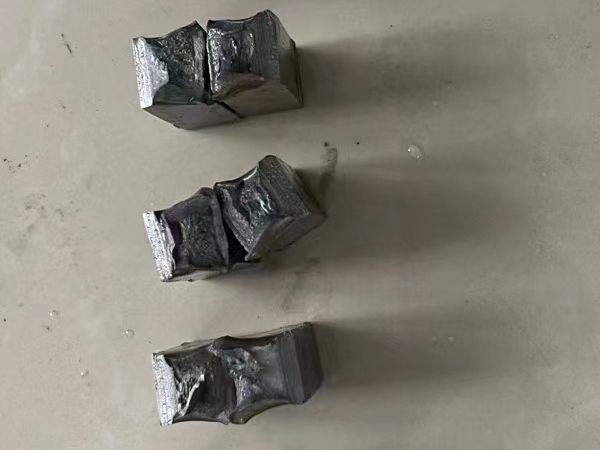

Surfacing Forming Flange Tensile Properties Testing

Heat treatment of Surfacing Forming Flange

Surfacing Forming Flange packaging and delivery

NOTE:Composite Flange is a strong corrosion resistant alloy product. Please contact the customer service before ordering.