SA-508Gr.3CL.1 is a material specification in the American Society of Mechanical Engineers (ASME) standard used for manufacturing high-strength low alloy steel forgings. In this specification, SA-508Gr.3CL.1 represents the material requirements that comply with Grade3 and Class1 in the SA-508 standard.

The SA-508 standard is a material standard commonly used in nuclear power plants and chemical equipment, covering the requirements for low alloy steel forgings. Gr.3 indicates that the material is Grade 3 steel, while CL.1 indicates that the material meets the requirements of Class 1.

The chemical composition of SA-508Gr.3CL.1 forgings can refer to the following table:

| C | Mn | Si | P | S | Ni | Cr | Mo | Cu | |

|---|---|---|---|---|---|---|---|---|---|

| % | ≤0.20 | 1.00-1.50 | ≤0.15 | ≤0.025 | ≤0.010 | 3.00-4.00 | ≤1.00 | ≤0.70 | ≤0.50 |

Note: The above chemical composition data is for reference only, and specific composition requirements should be based on relevant standard documents and specifications. In practical applications, the requirements for chemical composition may vary depending on specific product specifications and manufacturing standards.

The manufacturing process of SA-508Gr.3CL.1 forgings generally includes the following steps:

1. Raw material preparation: According to the engineering design and material requirements, select SA-508Gr.3CL.1 steel billets that meet the specified chemical composition and mechanical properties as raw materials.

2. Heating: Heat the SA-508Gr.3CL.1 steel billet to the appropriate forging temperature. The forging temperature is usually above the recrystallization temperature of the material to ensure that the material has good plasticity and malleability.

3. Forging: Put the heated SA-508Gr.3CL.1 steel billet into the forging equipment, and apply force through forging machines or hammering to cause plastic deformation of the steel billet under the action of the forging die, ultimately forming the desired shape. During the forging process, it is necessary to control parameters such as temperature, pressure, and deformation speed to achieve good forging results.

4. Heat treatment: Heat treatment is performed on forgings, commonly used methods include normalizing, quenching, and tempering. Heat treatment can adjust the microstructure and mechanical properties of forgings to achieve the strength and toughness required by the design.

5. Inspection and repair: Conduct dimensional inspection, defect inspection, and performance inspection on forgings to ensure that they meet the specified quality standards and technical requirements. If defects or non conformities are found, they need to be repaired or remade.

6. Surface treatment: Surface treatment is applied to forgings, such as rust removal, sandblasting, or coating, to improve their corrosion resistance and aesthetics.

7. Final inspection and confirmation: Conduct final quality inspection and confirmation on finished forgings, including visual inspection, dimensional testing, mechanical performance testing, etc.

The specific manufacturing process of SA-508Gr.3CL.1 forgings may vary depending on the shape, size, and requirements of different components. In actual production, relevant manufacturing process specifications and engineering requirements should be referred to, combined with equipment and process conditions, to carry out reasonable process design and control, to ensure the production of high-quality forgings that meet the requirements.

The SA-508Gr.3CL.1 forging has the following characteristics and applications:

1. High strength: SA-508Gr.3CL.1 forgings have high strength and can maintain stable mechanical properties in high stress and high temperature environments. This makes it very suitable for engineering applications that can withstand heavy loads and high stresses.

2. Corrosion resistance: SA-508Gr.3CL.1 forgings have good corrosion resistance in common corrosive media, and can resist the corrosion of acid, alkali and other corrosive media to a certain extent. They are suitable for some occasions with corrosive environmental requirements.

3. Low temperature performance: SA-508Gr.3CL.1 forgings have good low-temperature toughness and crack resistance, suitable for applications under low-temperature conditions, such as low-temperature working environments in nuclear power plants.

4. Chemical composition and mechanical properties: The specific chemical composition and mechanical properties requirements of SA-508Gr.3CL.1 forgings can be found in the SA-508 standard document. These performance data include the tensile strength, yield strength, elongation, impact toughness, etc. of the material.

SA-508Gr.3CL.1 forgings are widely used in fields such as nuclear power plants, petrochemicals, chemical and energy industries. It is commonly used to manufacture key components that require high strength and corrosion resistance, such as nuclear reactor vessels, pressure vessels, petrochemical equipment, turbine generator components, etc.

In the field of shipbuilding, SA-508Gr.3CL.1 forgings may be used to manufacture the following ship components:

1. Hull structural components: SA-508Gr.3CL.1 forgings can be used to manufacture structural components of the hull, such as the hull frame, hull partitions, and hull stiffeners. These components need to have high strength and good welding performance to ensure the structural strength and overall stability of the ship.

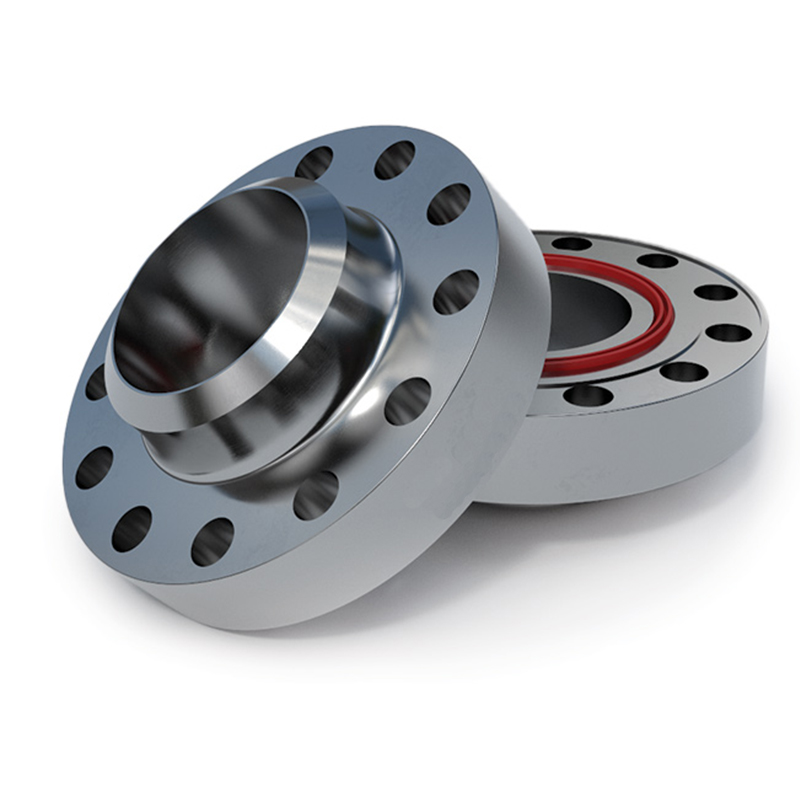

2. Ship pressure vessels: SA-508Gr.3CL.1 forgings can be used to manufacture pressure vessels on ships, such as oil tanks, water tanks, gas storage containers, etc. These pressure vessels need to be able to withstand high pressure and various media, and require good sealing and corrosion resistance.

3. Ship propulsion system components: SA-508Gr.3CL.1 forgings may be used to manufacture ship propulsion system components, such as propeller shafts, propeller blades, bearing seats, etc. These components typically require high strength and fatigue resistance to withstand the vibration and torsional forces of ships during navigation.

4. Marine valves and pipe fittings: SA-508Gr.3CL.1 forgings can be used to manufacture marine valves, pipe fittings, and pipe supports. In the pipeline system of ships, these components need to have good sealing performance, pressure resistance, and corrosion resistance.

The specific requirements and material selection for ship construction may vary depending on factors such as ship type, classification society requirements, and navigation environment.

The production process of SA-508Gr.3CL.1 forgings is complex, with high technical requirements and expensive material prices. Many orders require third-party on-site supervision and the issuance of EN102043.2 quality certificate. Our company welcomes inquiries from customers.