GET IN TOUCH WITH NFI STEEL

Inconel 718 Pipe Fittings-UNS N07718 Butt Weld Pipe Fittinges

Inconel 718 Pipe Fittings as per ASME/ANSI B16.9 in Types of 90 Degree Elbow Long Radius, 90 Degree Short Radius, 45 Degree Elbow Long Radius, 45 Degree Elbow Short Radius, 180 Degree Elbow, Equal Tee, Unequal Tee, Reducing Tee, Round Cap, Concentric Reducer, Eccentric Reducer, Stub Ends etc. Certified in China EN10204 3.1 EN10204 3.2 .

NR. 2.4668 BUTTWELD FITTINGS, UNS N07718 PIPE FITTINGS, ALLOY 718 BUTTWELD ELBOW, Inconel 718 SEAMLESS BUTT WELD FITTINGS EXPORTER, Inconel 718 LONG RADIUS BEND, Inconel 718 PIPE FITTINGS SUPPLIER.

Nickel 200/201 Pipe Fittings Manufacturer, Supplier, Stockholder in China.

▶What is Inconel 718 Butt weld Pipe Fittings

▶Standard Specification For N07718 Pipe Fittings

▶Types Of Inconel 718 Buttweld Pipe Fittings

▶Inconel 718 45° Elbow

▶Inconel 718 90° Elbow

▶Inconel 718 180° Elbow

▶Inconel 718 Equal Tee

▶Inconel 718 Concentric Reducer

▶Inconel 718 Eccentric Reducer

▶Inconel 718 Long Radius Elbow

▶Inconel 718 Short Radius Elbow

▶N07718 End Pipe Cap

▶N07718 Stub End

▶N07718 Cross

▶N07718 Reducing Tee

▶N07718 3D Bend

▶N07718 5D Bend

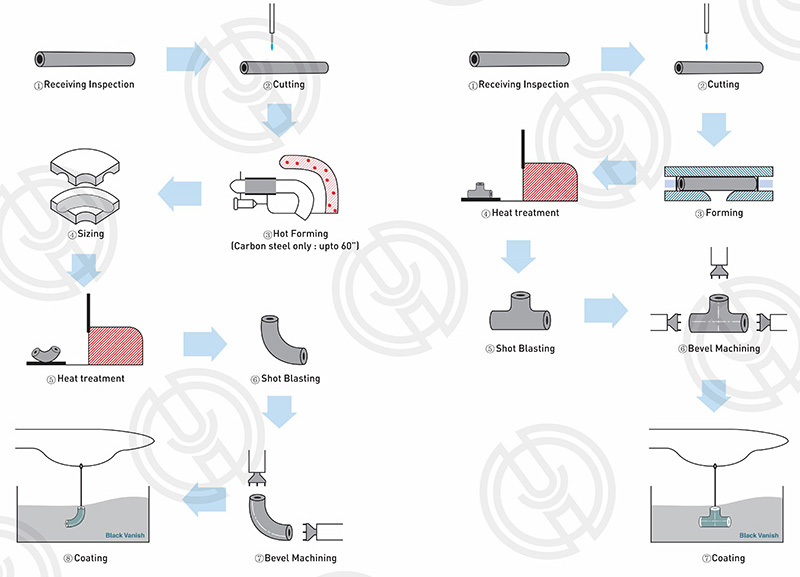

The Inconel 718 Pipe Fittings we produce are mainly made of seamless steel pipes and straight seam steel pipes through stamping production process, and then the finished products are manufactured through heat treatment, grinding and polishing, pickling and shot blasting.

The manufacturing standards of Inconel 718 Pipe Fittings produced by us include: ASME / ANSI B16.9, MSS SP75, JIS B2312, JIS B2313, EN10253, GB / T12459, etc. the pipe fitting standards of Inconel 718 Pipe Fittings include: Inconel 718 、2.4668、N07718, etc.

Each product of Inconel 718 produced by Cangzhou Enfei Pipe Equipment Co., Ltd. needs to undergo strict testing before it can be delivered to the customer with permanent steel seal.

In addition, the raw materials for manufacturing Inconel 718 are the products of the most excellent steel pipe manufacturers in China.

The raw material purchasers include Shanghai Baosteel, Valin steel, Tianjin seamless steel, Baotou Steel, Taiyuan Steel, Zhejiang Yongshang,Jiangsu Wujin,and internationally renowned raw material manufacturers SMC,ATI,VDM,Carpenter Technology Corporation,Imphy Alloys,Hitachi,Nippon YAKIN.

The raw material standards areASTM B/SB167, ASTM B/SB163,ASTM B/SB444,ASTM B/SB517,ASTM B/SB516,ASTM B474,ASTM B/SB705, ASTM B474, ASTM B/SB704 , etc.

The product thickness is SCH10S SCH20S SCH40S SCH80S STD-SCHXXS, and the product specification is 1/8-60 inches to meet customers’ various choices.

After years of customer accumulation and cooperation, Cangzhou Enfei Pipe Equipment Co., Ltd. has sent its products to North America, South America, Australia, the Middle East, Europe, South Korea and Japan.

Industrial Inconel 718 Pipe Fittings Test Certificates: Cangzhou Enfei Pipe Equipment Co., Ltd. offer its Products with Third Party Inspection also. The Inspection Agency can be nominated by clients or Dynamic Forge & Fittings can be arrange the TPI by World reputed Agencies like Bureau Veritas, ABS, SGS and many other.

Inconel 718 Pipe Fittings Specification

| Butt Weld Fitting Collection | ASTM B366 Inconel 718 LR 90 Elbow,N07718 LR 45 Elbow,ASTM B366 Inconel 718 SR90 Elbow

N07718 LR 180 degree Bend,ASTM B366 Inconel 718 SR 180 degree Bend,N07718 Tee ASTM B366 Inconel 718 Reducing Tee,N07718 Concentric Reducer,ASTM B366 Inconel 718 Eccentric Reducer N07718 Weldolet,N07718 Welded Stub |

|||||

| Size | 1/2〞(DN15)to 60〞(DN1500) | |||||

| Sch. & Swg. | Sch.5 to Sch.XXS | |||||

| Surface Treatment | Antirust Paint,Oil Black Paint,Yellow Transparent,Zinc Plated,Cold and Hot Dip Galvanized | |||||

| Manufacturing process | Moulded/Cold extrusion/Heat treatment | |||||

| Manufacturing Standards | ASME B16.9 EN10253-4 JIS GOST EEMUA234 GB/T12459 GB/T13401 | |||||

Chemical Composition of Inconel 718 Butt weld Fittings

| Ni | Cr | Fe | Mo | Nb+Ta | C | Mn | Si | Ph | S | Ti | Cu | B | Al | Co | |

| Min | 50 | 17 | Bal | 2.8 | 4.75 | – | – | – | – | – | 0.65 | – | – | 0.2 | – |

| Max | 55 | 21 | – | 3.3 | 5.5 | 0.08 | 0.035 | 0.35 | 0.015 | 0.015 | 1.15 | 0.3 | 0.0006 | 0.8 | 1 |

Inconel 718 Equivalent Material

| Grade | UNS No | Old British | Euronorm | GOST | Japanese JIS | ||

| BS | En | No | AFNOR | ||||

| Inconel 718 Pipe Fittings | N07718 | – | – | 2.4668 | – | – | – |

Cast Inconel 718 Mechanical Properties

| Element | Tensile Strength | Yield Strength (0.2%Offset) | Elongation | Density | Melting Point |

| Inconel 718 Pipe Fittings | Psi – 80,000 , MPa – 550 | Psi – 32,000 , MPa – 220 | 30% | 8.14 g/cm3 | 1400 °C (2550 °F) |

Physical Properties Of UNS N07718 Pipe Fittings

| Density, lb/in3 | Melting Range | Specific Heat at 70°F, Btu/lb °F | Curie Temperature, °F(°C) | Permeability at 200 oersted and 70°F | ||||

| Annealed | Aged and Annealed | °F | °C | at 21°C, J/kg °C) | Annealed Material | Aged Material and Annealed | Annealed Material | Aged Material and Annealed |

| 0.296 | 0.297 | 2300-2437 | 1260-1336 | 0.104(435) | <-320(<-196) | -170(-112) | 1.0013 | 1.0011 |

Inconel 718 Pipe Fittings inspection

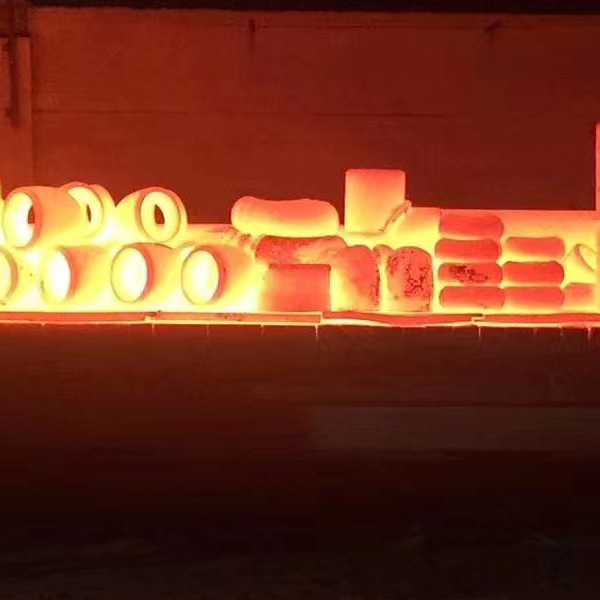

Heat treatment of Inconel 718 Pipe Fittings

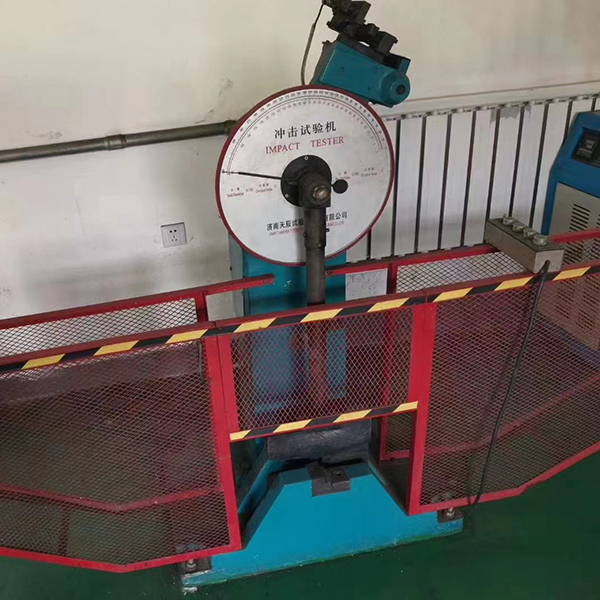

Mechanical properties and welding test of Inconel 718 Pipe Fittings

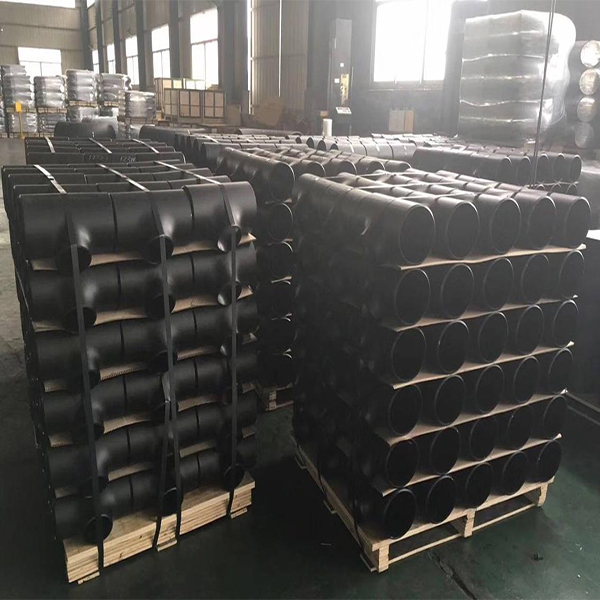

Inconel 718 Pipe Fittings packaging and delivery

NOTE:Inconel 718 Pipe Fittings is a strong corrosion resistant alloy product,Our company has a large number of stock, Please contact the customer service before ordering.

Related products

-

BUTT WELD FITTINGS

Incoloy 926 Pipe Fittings| ASTM B649 UNS N08926 Buttweld Fittings

Rated 0 out of 5Read more -

BUTT WELD FITTINGS

Inconel 725 Pipe Fittings-UNS N07725 Buttweld Pipe Fittinges

Rated 0 out of 5Read more -

BUTT WELD FITTINGS

ASTM A420 WPL6 Pipe Fittings-Low Temperature 45 ° elbow

Rated 0 out of 5Read more