Socket Weld Flanges: Compact Strength for High-Pressure Piping

Release Time:

Jun 25,2025

Engineered for small-diameter, high-performance systems where welding space is limited but reliability is critical.

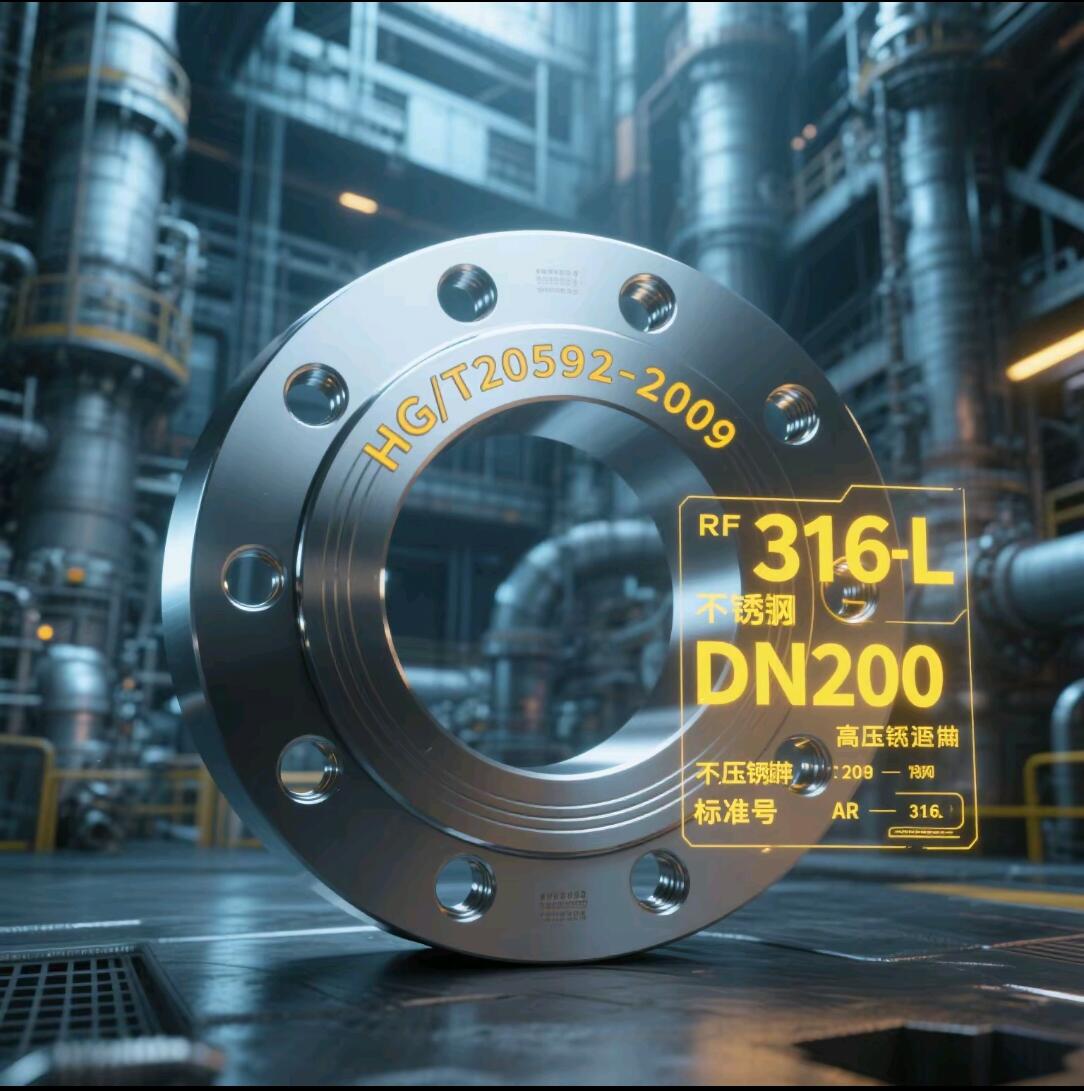

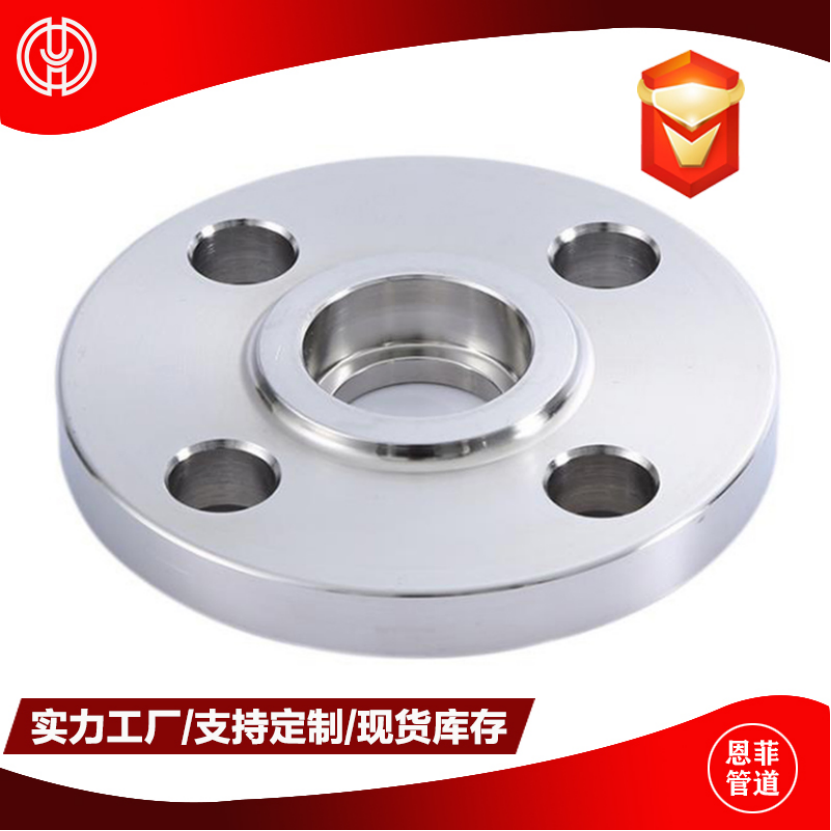

SOCKET WELD FLANGE

Structural Features:

A flange with a recessed socket to insert the pipe end before welding.

Designed for small-diameter, high-pressure piping systems.

Provides a smooth bore and better flow characteristics compared to some other flange types.

Available in RF / FF face types.

Welding Method:

The pipe is inserted into the socket until it contacts the shoulder, then fillet welded around the outer rim.

No need for full beveling or alignment as required in butt welding.

Ensures good alignment and structural strength for smaller pipe sizes.

Internal gap between pipe end and shoulder is usually maintained to allow for thermal expansion.

Applications:

Ideal for:

High-pressure, small-bore piping

Steam lines

Hydraulic systems

Chemical and petrochemical process lines

Especially used where leak-tightness and structural integrity are important, but welding space is limited.

Common Size Standards:

ASME B16.5: Typically available for sizes 1/2” – 2”, occasionally up to 4”

Pressure Ratings:

-Class 150, 300, 600, 900, 1500, 2500

(Similar to weld neck flange pressure classes)

Flange Face Types:

-RF (Raised Face)

-FF (Flat Face)

Materials:

-Carbon Steel, Stainless Steel, Alloy Steel, Duplex Stainless Steel

Recommendation:

Socket weld flanges are a preferred choice for small-diameter, high-pressure systems that require strong weld joints but have limited welding access.

Their compact design, ease of installation, and leak resistance make them popular in high-performance industrial pipelines.

Key words:

Other News