Reducer Flanges: Compact Transitions for Complex Piping Systems

Release Time:

Jun 24,2025

Engineered for efficiency—seamlessly connect different pipe sizes while maintaining pressure integrity and minimizing turbulence.

REDUCER FLANGE

Structural Features:

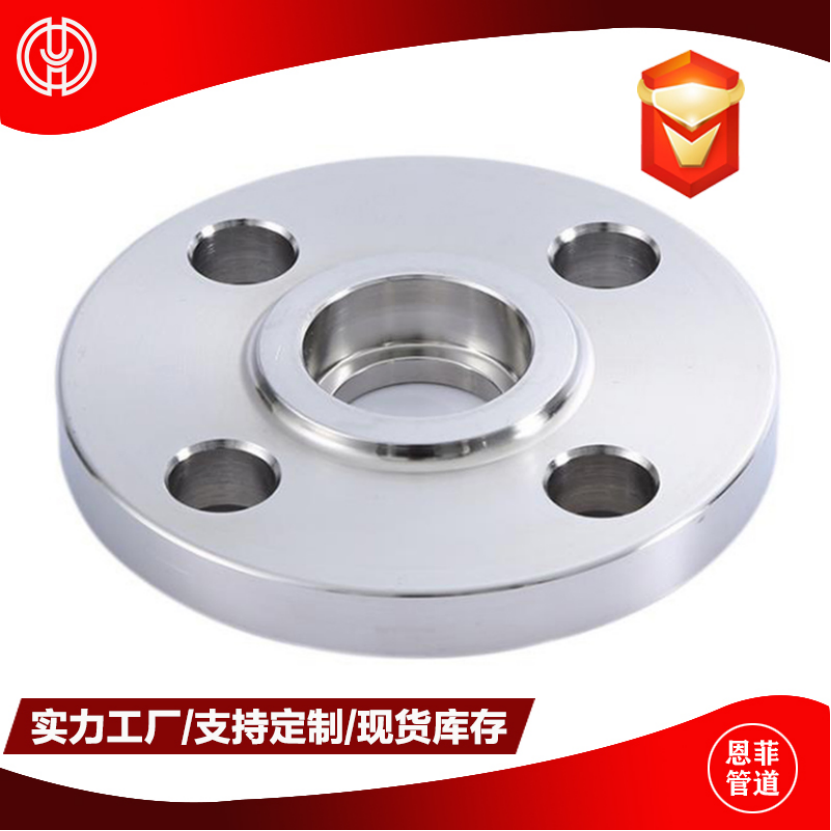

A flange with an integrated concentric or eccentric reducer, used to connect pipes of different diameters.

Combines the function of a flange and a reducer into a single compact unit.

Helps maintain flow efficiency and reduces turbulence in transitions between different pipe sizes.

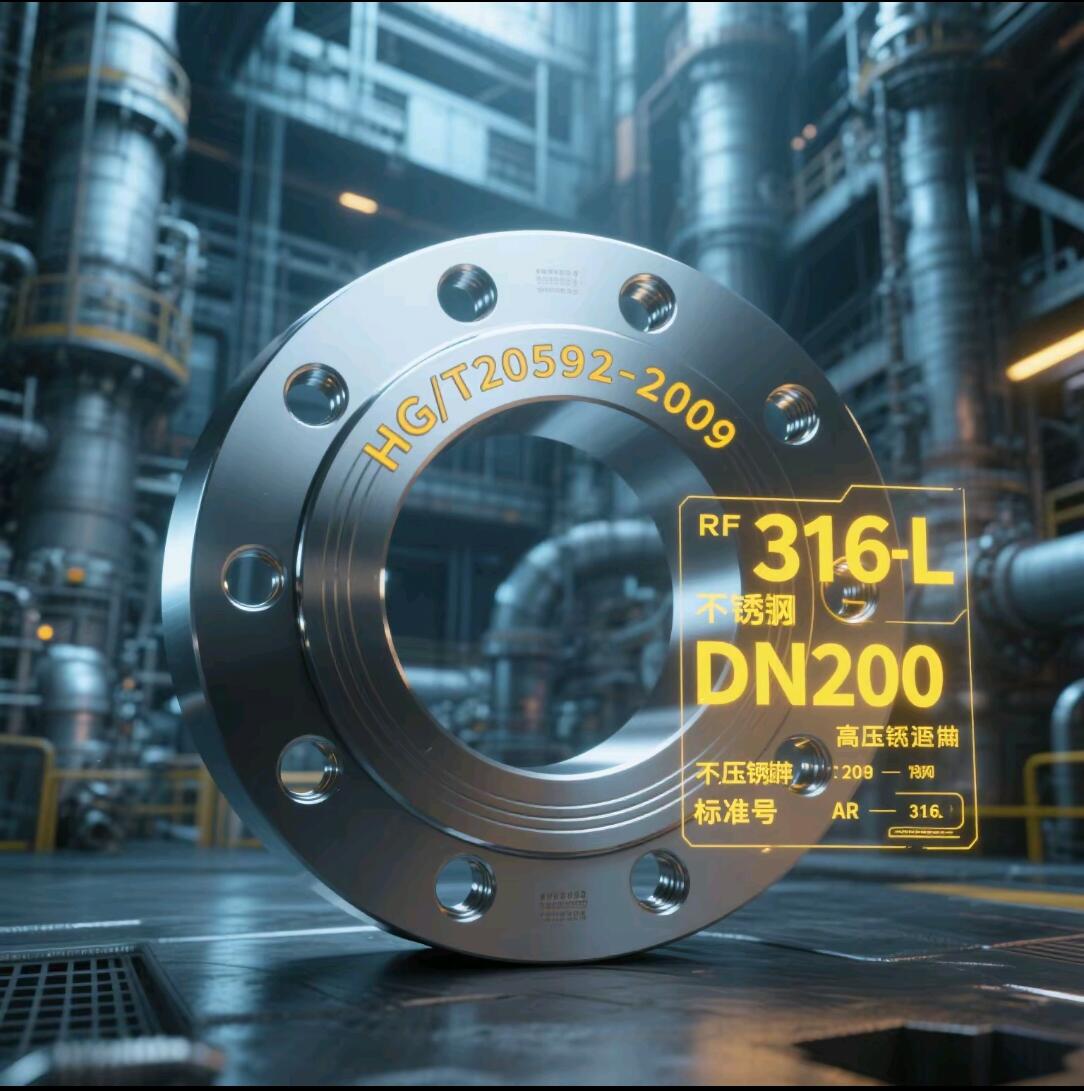

Available in RF / RTJ / FF face types.

Welding Method:

Typically joined by butt welding to the larger pipe, and bolted to the matching flange on the smaller pipe side.

Welding quality and alignment are important to ensure smooth flow and structural strength.

Eccentric designs are used to prevent air pockets in horizontal pipelines.

Applications:

Used in systems requiring:

Pipe size transitions while maintaining flange connections

Flow rate control and pressure adjustment

Compact solutions without needing a separate reducer and flange

Common in:

Oil & Gas

Petrochemical Plants

Water Treatment Systems

Power Plants

Shipbuilding & Offshore Facilities

Common Size Standards:

-Customized according to project specifications

-Compatible with ASME B16.5 and B16.47 flange dimensions

Pressure Ratings:

-150# to 2500#, depending on material and design

(Same pressure class as corresponding standard flanges)

Flange Face Types:

-RF (Raised Face)

-RTJ (Ring-Type Joint)

-FF (Flat Face)

Materials:

Carbon Steel, Stainless Steel, Alloy Steel, Duplex Stainless Steel

Recommendation:

Reducer flanges provide a streamlined, space-saving solution for connecting different pipe sizes.

Ideal for projects that demand compact, efficient transitions without sacrificing flow or pressure control.

Highly recommended in high-performance piping systems where layout optimization is critical.

Key words:

Other News