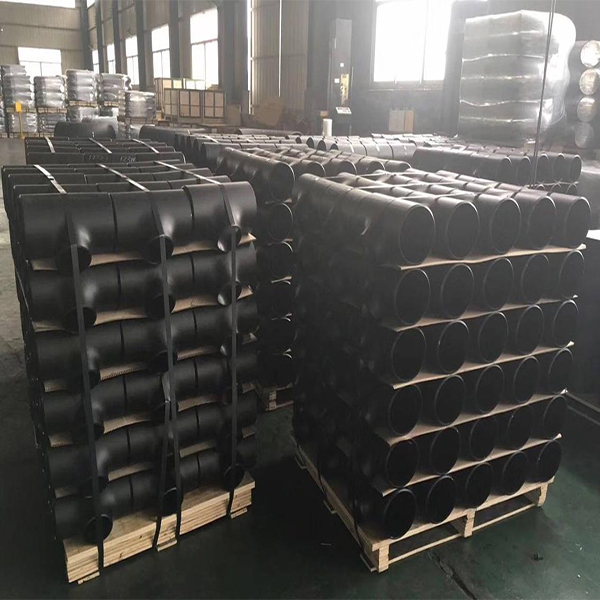

ASTM A234 WP91 Buttweld Elbow,ASTM A234 WP91 Buttweld Tee,ASTM A234 WP91 Buttweld Concentric Reducer,ASTM A234 WP91 Buttweld Fittings

ASTM A234 WP91 Alloy Steel Pipe Fittings are carbon steel pipe fittings used in high-temperature and high-pressure conditions, commonly used in industries such as petroleum, chemical, and power. The following is an introduction to ASTM A234 WP91 Alloy Steel Pipe Fittings:

1. Material composition: ASTM A234 WP91 Alloy Steel Pipe Fittings are made of carbon steel, mainly composed of carbon (C) and a small amount of alloy elements such as chromium (Cr), molybdenum (Mo), molybdenum iron (Mo Fe), etc. Among them, the chromium content is relatively high, which enhances the antioxidant capacity of the pipe fittings.

2. Pressure bearing capacity: ASTM A234 WP91 Alloy Steel Pipe Fittings have high pressure bearing capacity and can operate safely under high-pressure conditions. It meets the requirements of high-temperature and high-pressure pipeline systems and can withstand large pressures and temperatures.

3. High temperature resistance: ASTM A234 WP91 Alloy Steel Pipe Fittings have good high temperature resistance and can operate stably in high temperature environments for a long time. It can withstand thermal cycling and stress at high temperatures, and is not prone to deformation and fracture.

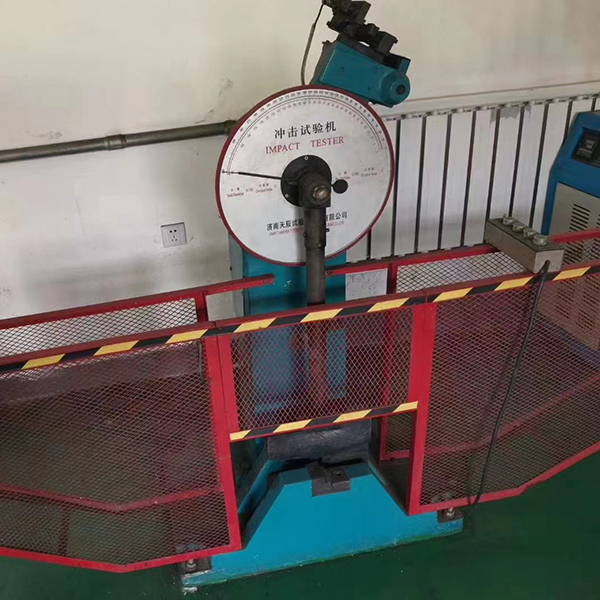

Mechanical properties and welding test of ASTM A234 WP91 Alloy Steel Pipe Fittings

4. Corrosion resistance: ASTM A234 WP91 Alloy Steel Pipe Fittings have a certain degree of corrosion resistance under normal working conditions, and are suitable for the transportation and treatment of general media. However, in corrosive media such as strong acids and alkalis, it may be necessary to use materials with better corrosion performance or adopt coating protection measures.

5. Application field: ASTM A234 WP91 Alloy Steel Pipe Fittings are commonly used in high-temperature and high-pressure pipeline systems, and are widely used in the petroleum and natural gas industry, chemical industry, power industry, and other fields. It is often used to connect pipelines and equipment, such as elbows, pipe joints, flanges, pipe caps, etc.

ASTM A234 WP91 Alloy Steel Pipe Fittings Chemical Composition

| Grade | C | Mn | Si | S | P | Cr | Mo |

| A234 WP91 | 0.08-0.12 | 0.3-0.6 | 0.2-0.5 | ≤0.02 | ≤0.015 | 8-9.5 | 0.85-1.05 |

Mechanical properties of ASTM A234 WP91 Alloy Steel Pipe Fittings

| Grade | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation % |

| A234 WP91 | ≥590 | ≥415 | ≥20 |

It should be noted that when selecting and using ASTM A234 WP91 Alloy Steel Pipe Fittings, it is necessary to design, manufacture, and install them according to specific working conditions and application requirements, following corresponding standards and specifications. During use, regular inspections and maintenance are also required to ensure the safe operation of the pipeline system.

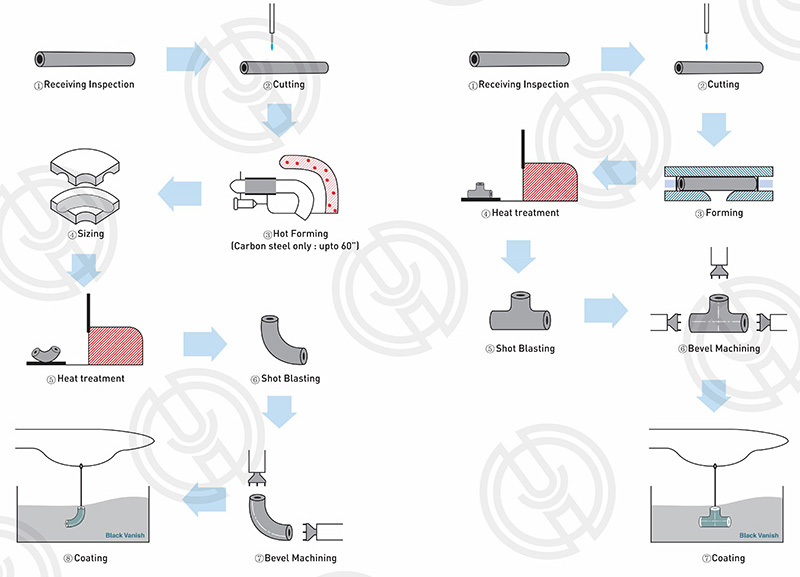

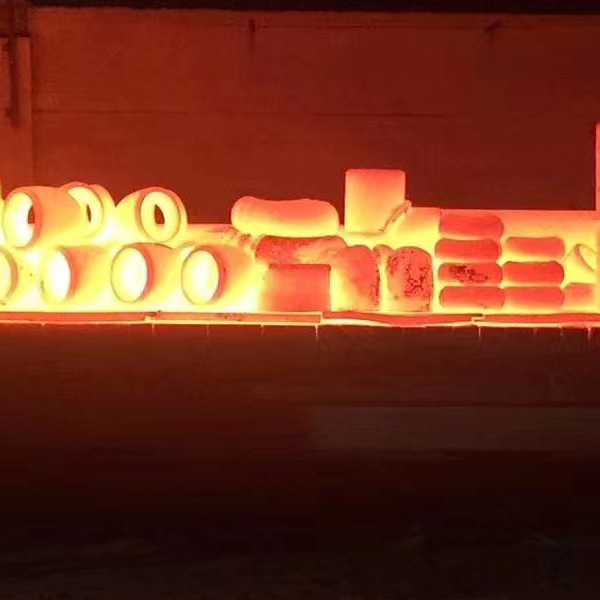

Heat treatment of ASTM A234 WP91 Alloy Steel Pipe Fittings

ASTM A234 WP91 Alloy Steel Pipe Fittings usually require heat treatment during the manufacturing process to obtain the required mechanical properties and microstructure. The following is a common heat treatment process for ASTM A234 WP91 Alloy Steel Pipe Fittings:

1. Preheating: Before heat treatment, ASTM A234 WP91 Alloy Steel Pipe Fittings usually require preheating treatment. The preheating temperature is usually between 200 ° C and 600 ° C, with the aim of uniformly heating the pipe fittings to reduce differences in thermal stress and cooling rate.

2. Solution treatment: After preheating, ASTM A234 WP91 Alloy Steel Pipe Fittings are usually subjected to solution treatment. The solution treatment temperature is usually between 980 ° C and 1050 ° C, and the time depends on the size and material thickness of the pipe fittings. The purpose of solid solution treatment is to dissolve alloy elements in the matrix, so that the pipe fittings have a uniform organizational structure.

3. Quenching treatment: After solid solution treatment, ASTM A234 WP91 Alloy Steel Pipe Fittings usually require quenching treatment. The quenching temperature is usually between 980 ° C and 1050 ° C, and the time is relatively short. The purpose of quenching is to quickly cool the pipe fittings to obtain high hardness and finer microstructure.

4. Tempering treatment: After quenching, ASTM A234 WP91 Alloy Steel Pipe Fittings usually require tempering treatment to reduce brittleness and stress during quenching. The tempering temperature is usually between 690 ° C and 760 ° C, and the time depends on the size of the pipe fittings and the required mechanical properties. The purpose of tempering is to reduce hardness, increase toughness, and achieve the required mechanical properties of the pipe fittings.

ASTM A234 WP91 Alloy Steel Pipe Fittings inspection

For the welding of ASTM A234 WP91 Alloy Steel Pipe Fittings, post weld heat treatment is usually required to eliminate residual stress and improve the mechanical properties of the weld seam. The following are common steps for welding heat treatment of ASTM A234 WP91 Alloy Steel Pipe Fittings:

1. Preheating: Before welding, ASTM A234 WP91 Alloy Steel Pipe Fittings and welding materials (such as welding wires) usually require preheating treatment. The preheating temperature is usually between 200 ° C and 300 ° C, with the aim of reducing residual stress and cooling rate differences during welding, thereby reducing the brittleness of welded joints.

2. Welding: Select appropriate welding methods (such as manual arc welding, gas shielded welding, etc.) for welding, and ensure appropriate welding process parameters, such as welding current, voltage, and welding speed. At the same time, it is necessary to ensure the accurate alignment and quality of the welded joints.

3. Post Weld Heat Treatment (PWHT): After welding is completed, ASTM A234 WP91 Alloy Steel Pipe Fittings often require Post Weld Heat Treatment (PWHT). The temperature and time of post weld heat treatment need to be determined according to specific welding process specifications and requirements.

-Solution treatment: Usually carried out at a temperature of approximately 760 ° C to 790 ° C, with a duration of 2 hours. The purpose of solution treatment is to dissolve alloy elements in the weld seam, redistribute them, and produce a uniform grain structure.

-Tempering treatment: After solid solution treatment, followed by tempering treatment. The typical tempering temperature is 690 ° C to 760 ° C, and the time is usually 2 hours. The purpose of tempering is to improve the toughness of the weld seam and reduce residual stress, thereby improving the mechanical properties of the welded joint.

ASTM A234 WP91 Alloy Steel Pipe Fittings packaging and delivery

It should be noted that the temperature and time parameters for post weld heat treatment ofASTM A234 WP91 Alloy Steel Pipe Fittings should comply with relevant standards and specifications, and adjustments need to be made according to specific welding materials, welding processes, and application requirements. During the post weld heat treatment process, the heating and cooling rates should be strictly controlled to avoid excessive temperature gradients and residual stresses. In addition, after the completion of post weld heat treatment, appropriate cooling and cleaning treatment is also required to ensure the quality and reliability of the welded joint.