Opposite Ring Flange: Enhancing Safety and Reliability in Piping Systems

Release Time:

Sep 10,2025

Discover the advantages of forged Opposite Ring Flanges for offshore, oil & gas, and chemical piping systems. Learn about standards, materials, and applications from NFI.

In the field of industrial piping and offshore engineering, choosing the right flange solution is critical to ensuring long-term system safety and reliability. Among the various types of forged flanges, the Opposite Ring Flange has become a preferred choice for demanding environments such as oil & gas pipelines, shipbuilding, offshore platforms, and chemical processing plants.

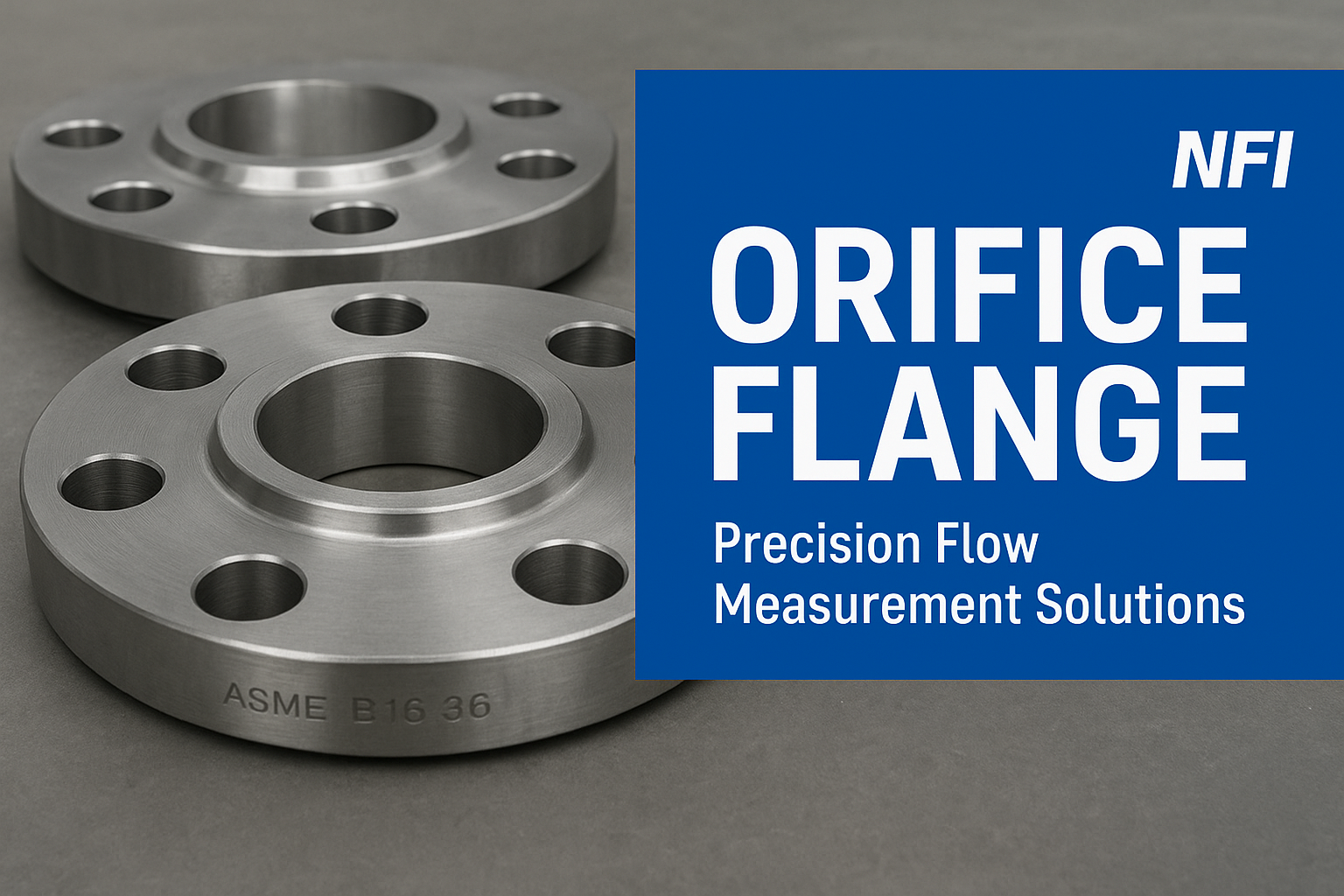

At NFI, we specialize in the production of high-quality forged flanges, including Opposite Ring Flanges that meet international standards such as ANSI, DIN, JIS, and GB. Our flanges undergo rigorous forging, heat treatment, and non-destructive testing (NDT) to guarantee strength, durability, and safety under extreme working conditions.

👉 Learn more about our product here: https://www.enfipipe.com/products_details/163.html

Key Advantages of Opposite Ring Flanges

High Strength Forging – Manufactured through precision forging, these flanges ensure excellent mechanical properties and resistance to fatigue.

Reliable Sealing – The opposite ring design provides better sealing under high pressure, making it ideal for critical connections.

Wide Material Options – Available in carbon steel, stainless steel, and alloy steel to suit different industry applications.

Certification & Standards – NFI flanges can be supplied with 3.2 MTC and are certified by leading classification societies including ABS, BV, LR, DNV, and CCS.

Applications Across Industries

Oil & Gas: High-pressure pipelines and offshore drilling systems.

Marine & Shipbuilding: Piping systems in vessels and offshore structures.

Chemical Plants: Corrosion-resistant solutions for chemical processing lines.

Power Generation: Steam, cooling, and energy distribution systems.

With decades of expertise, NFI continues to deliver customized solutions for global clients, ensuring every Opposite Ring Flange meets the highest quality standards.

Why Choose NFI as Your Flange Partner?

Comprehensive Certification: Multiple approvals from ABS, BV, LR, DNV, NK, CCS.

Tailored Engineering Support: Our technical team provides customized solutions based on client needs.

Global Reach: Trusted by clients in Asia, Europe, the Middle East, and North America.

Sustainable Manufacturing: Environmentally friendly processes that align with international best practices.

👉 For detailed specifications and inquiries, visit: https://www.enfipipe.com/products_details/163.html

Conclusion

As industries continue to demand safer and more reliable piping solutions, the Opposite Ring Flange stands out as a proven, high-performance option. Backed by strict quality control and global certifications, NFI remains committed to providing world-class flange solutions for complex engineering projects.

Other News