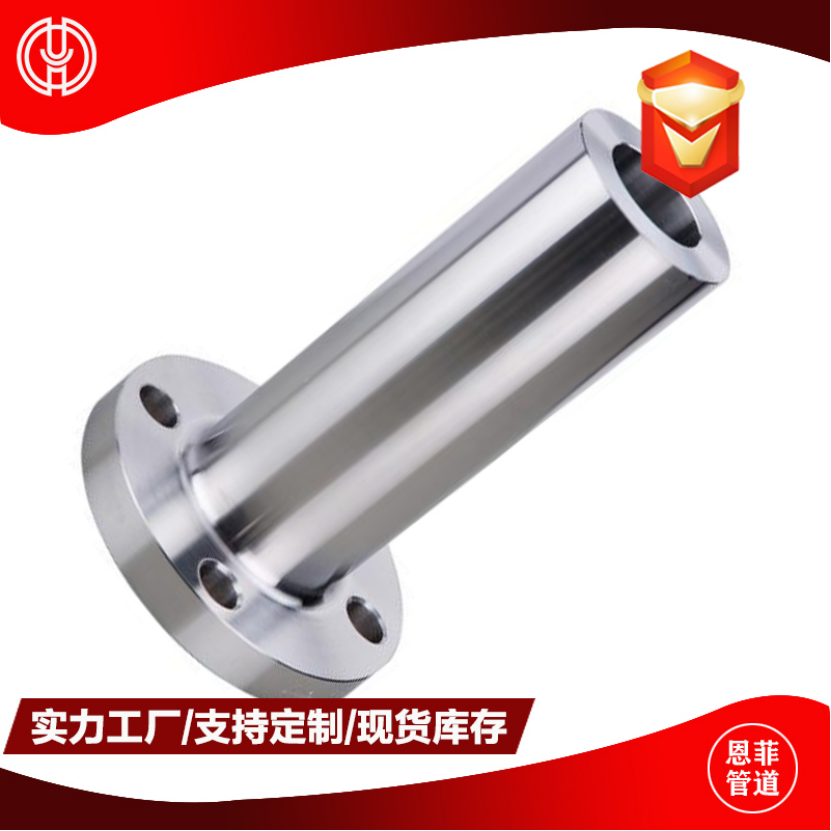

Long Weld Neck Flange – Engineered Strength for Demanding Applications

Release Time:

Jun 16,2025

Designed for pressure vessels and critical systems, our long weld neck flanges ensure structural integrity, smooth flow transition, and exceptional performance under high-pressure and high-temperature conditions.

Long Weld Neck Flange

Engineered Strength for Pressure-Critical Applications

🔩 Structural Features

One-piece forged flange with an extended tapered neck

Designed to replace pipe nipples or weld-on nozzles

Tapered neck provides reinforcement and ensures smooth flow transition

Commonly used in:

Pressure vessels

Heat exchangers

Storage tanks

Available flange face types:

RF (Raised Face)

RTJ (Ring-Type Joint)

FF (Flat Face)

🔧 Welding Method

Butt-welded at the base of the neck

Forms a continuous, integral structure with vessel or piping

Ensures high mechanical strength and stress resistance

Requires high-quality welding — often with:

Radiographic (RT) or

Ultrasonic (UT) non-destructive testing

🛠️ Applications

Ideal for critical industrial systems such as:

🛢 Pressure vessels

🏗 Column towers

🔥 Heat exchangers

🧊 Cryogenic systems

🧪 Chemical processing plants

⚡ Power generation equipment

🔩 Custom fabrications requiring nozzle reinforcement

📏 Size Standards

Range: 1/2” to 120” (DN15–DN3000)

Reference Standards:

ASME B16.5 (2”–24”)

ASME B16.47 (Above 24”)

MSS-SP-44 (Large-diameter applications)

⚙️ Pressure Ratings

Class: 150#, 300#, 600#, 900#, 1500#, 2500#

Custom designs available for pressures exceeding standard ratings

🧪 Available Materials

Carbon Steel

Stainless Steel

Alloy Steel

Duplex Stainless Steel

Nickel Alloys

✅ Recommendation

Long Weld Neck Flanges are the optimal solution where:

High strength and structural continuity are required

Reinforced nozzles or extended necks are necessary

Applications demand reliable performance under extreme conditions (pressure, temperature, stress)

Key words:

Other News