Stainless steel composite plate

Release Time:

Feb 11,2024

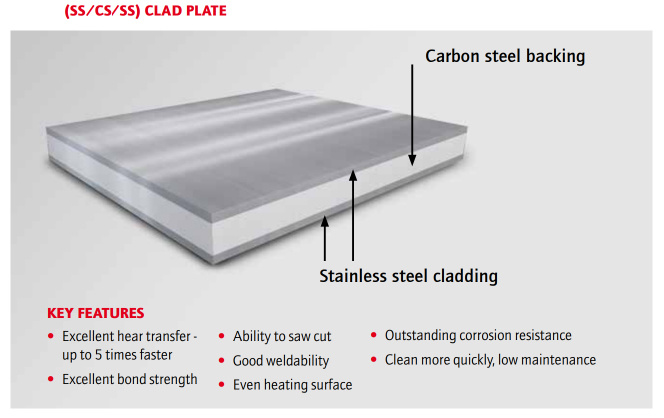

Stainless steel composite steel plate is a high-efficiency and energy-saving material formed by hot rolling with carbon steel as the base material and stainless steel as the cladding material.

Stainless steel composite steel plate is a high-efficiency and energy-saving material formed by hot rolling with carbon steel as the base material and stainless steel as the cladding material. Products are widely used in stone, petroleum, chemical, salt, water, power and other industries, lamination materials including austenite, ferrite or martensitic block and duplex stainless steel, nickel-based alloys (825, C-276) and pure titanium (TA1, TA2).

The matrix of bimetallic composite is carbon steel, and the composite layer is a material with special physical and chemical properties, and a solid metallurgical bond is formed between the matrix and the composite layer.

Stainless steel composite steel plate has both the basic mechanical properties of the layer and the special physical and chemical properties of the layer, the performance is good, and the cost is reduced by 40%-60%.

Composite steel sheet - Two manufacturing methods

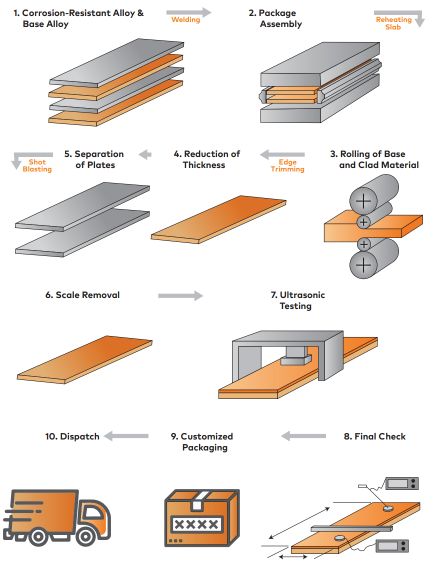

1. Composite steel plate - hot rolling

The hot rolled composite plate process is to roll carbon steel substrate and stainless steel plate in a physically pure state under high vacuum conditions, and the two metals are diffused during the rolling process to achieve complete metallurgical combination.

2. Composite steel plate - explosive ZHA composite

The explosive composite plate is the stainless steel plate overlapping on the carbon steel substrate, the stainless steel plate and the carbon steel substrate with a certain distance cushion, laying explosives on the stainless steel plate, the energy of the explosive explosion makes the stainless steel plate high-speed impact on the carbon steel substrate, producing high temperature and high pressure, to achieve the solid combination of the interface of the two materials.

Single-sided recombination

Double-sided recombination

Stainless steel composite steel sheet supply scope

| Base (2-60) + layer (0.5-8) *1450⁓4000L (≤15000) | ||||||

| Base material | recombination | Laminated material | Thickness specification,mm | Enforce standards | ||

| Structural steel | Q235/ Q345/ Q345Q/ Q370Q etc. | Austenitic stainless steel | 304/ 304L/ 310S/ 321/ 316/ 316L/ 317/ 317L etc. | Base (2-60) + Layer (0.5-8) | ASTM A263/ ASTM A264/ ASTM A265/ JIS G3601/ JIS G3602/ JIS G3603/ GB/T8165/ NB/T47002/ YB/T4282/ GB/T8547 | |

| Vessel steel | Q245R/ Q345R/ 16MnDR/ A516 Gr70/ 09MnNiD etc. | Ferritic or martensitic stainless steel | 1Cr13/ 4Cr13/ 410/ 410S etc. | |||

| Pipeline steel | X60/ X65MS/ X70 etc. | Duplex stainless steel | 2101/ 2205/ S31803 etc. | |||

| Ship plate steel | A460/ A500 etc. | Nickel-based alloy or pure titanium | 825/ 625/ TA1/ TA2 etc. | |||

The application of stainless steel composite plates will be widely promoted in the future.

Key words:

Other News