Lined with PTFE steel pipe

- Commodity name: Lined with PTFE steel pipe

Product Introduction

The primary problem of the protection pipe of the directly buried pipeline is the reliability of strict waterproof, in addition to having good mechanical strength, steel sleeve due to high strength welded connection, waterproof sealing performance reliability is very high, in addition, its high temperature resistance performance is also unmatched by other external protection pipes.

In areas with high groundwater level, in order to ensure that groundwater does not affect the normal operation of steam directly buried pipelines, it is best to use a strong and closed steel pipe shell for the outer protective layer.

1. Anti-corrosion layer: protect the outer steel pipe to avoid corrosion of steel pipe, extend the service life of steel pipe.

2. Outer protection steel pipe: protect the insulation layer from groundwater erosion, support the working pipe and can withstand a certain external load to ensure the normal work of the working pipe.

3. Polyurethane foam layer: to ensure the temperature of the medium, to ensure that the surface of the outer protective tube is maintained at normal temperature.

4. Barrier and reflection layer: to ensure that organic foam materials do not enter the inorganic hard high temperature resistant layer; Reflect part of the heat of the high temperature resistant layer.

5. Inorganic hard insulation layer: high temperature resistance, to ensure the interface temperature between the organic insulation layer, to ensure that the foam is not carbonized.

6. Drag reduction layer: to ensure the free movement of thermal expansion and contraction of the working steel pipe.

7. Working steel pipe: ensure the normal flow of the conveying medium.

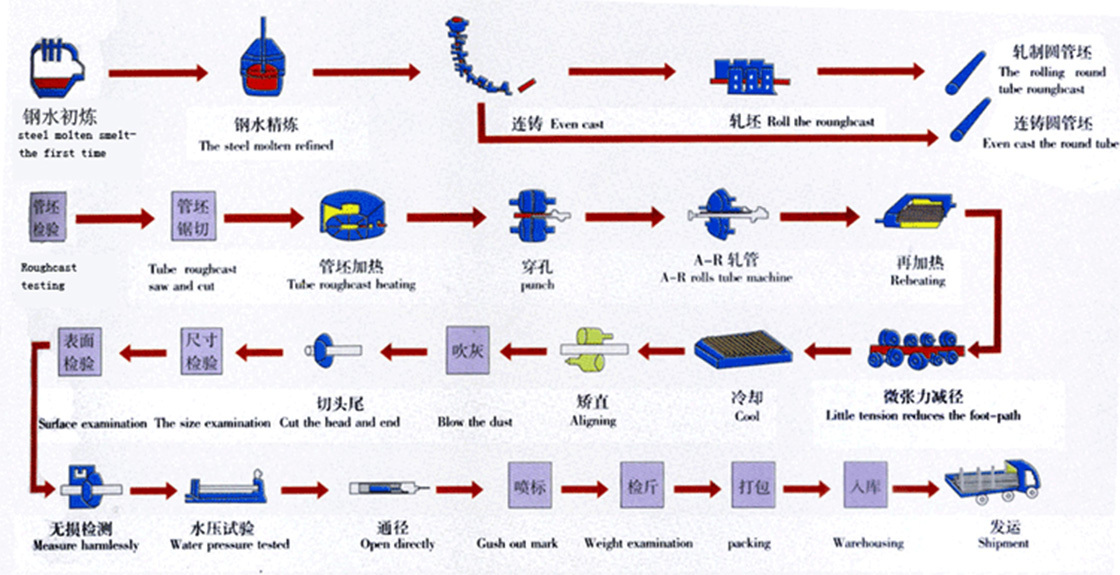

Process introduction

About delivery