Stainless steel high pressure 90° socket elbow

- Commodity name: Stainless steel high pressure 90° socket elbow

Product Introduction

The stainless steel high pressure 90° socket elbow is a crucial component in various industrial applications where high pressure and corrosive environments are common. This type of elbow is specifically designed to handle the demanding conditions of these industries, ensuring a reliable and long-lasting performance.

One key feature of the stainless steel high pressure 90° socket elbow is its durability. Made from high-quality stainless steel, this elbow is able to withstand high pressures and temperatures without compromising its structural integrity. This makes it an ideal choice for applications where safety and reliability are paramount.

In addition to its durability, the stainless steel high pressure 90° socket elbow also offers excellent corrosion resistance. This is particularly important in industries where the presence of corrosive materials can quickly degrade lesser-quality components. With this elbow, you can be confident that your system will remain free from corrosion for an extended period of time.

Overall, the stainless steel high pressure 90° socket elbow is a versatile and reliable component that is well-suited for a wide range of industrial applications. Its durability, corrosion resistance, and high-pressure capabilities make it an essential part of any system where performance and safety are top priorities.

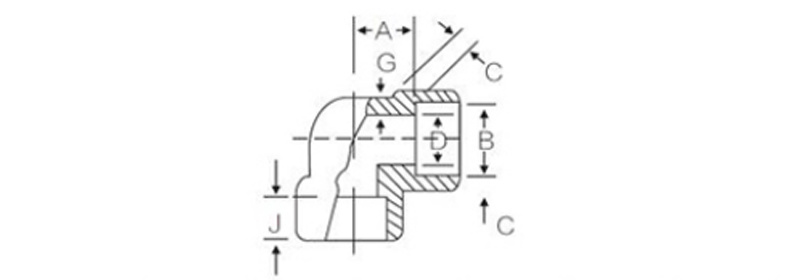

| Corresponding national standard title | Corresponding to the United States standard name | Supporting copper pipe outer diameter (mm) | Socket inside diameter B | Outside diameter | Jack depth J | Total height | Wall Thickness C | Through hole bore D | Body wall thickness G | Center to socket bottom (not shorter than)A | Weight (KG) |

| DN6 | 8 | 8.5 | 23 | 9.5 | 33 | 7.3 | 6.1 | 2. 41 | 6.1 | 0.09 | |

| DN6 | 1/8” | 10 | 10. 5 | 23 | 9.5 | 33 | 6.3 | 6.1 | 2. 41 | 6.1 | 0.09 |

| DN8 | 12 | 12. 5 | 23 | 9.5 | 33 | 5.3 | 8.5 | 3. 02 | 6.1 | 0.09 | |

| DN8 | 1/4” | 14 | 14.5 | 23 | 9.5 | 33 | 4.3 | 8.5 | 3. 02 | 6.1 | 0.09 |

| DN10 | 16 | 16. 5 | 27.5 | 9.5 | 37 | 5.5 | 11.8 | 3. 2 | 8.5 | 0.115 | |

| DN10 | 3/8” | 17 | 18.2 | 27.5 | 9.5 | 37 | 47 | 11.8 | 3. 2 | 8.5 | 0.115 |

| DN15 | 18 | 18.5 | 33 | 9.5 | 43 | 73 | 15 | 3. 72 | 15.5 | 0.22 | |

| DN15 | 20 | 20.5 | 33 | 9.5 | 43 | 6. 3 | 15 | 3. 72 | 15.5 | 0.22 | |

| DN15 | 1/2” | 22 | 22.3 | 33 | 9.5 | 43 | 5.4 | 15 | 3. 72 | 15.5 | 0.22 |

| DN20 | 25 | 25.5 | 39 | 9.5 | 53 | 6.8 | 99 | 3. 91 | 19 | 0.33 | |

| DN20 | 3/4” | 27 | 27.5 | 39 | 12.5 | 53 | 5.8 | 20.2 | 3. 91 | 19 | 0.33 |

| DN20 | 28 | 28.5 | 39 | 12.5 | 53 | 5.3 | 20.2 | 3. 91 | 19 | 0.33 | |

| DN25 | 32 | 32.5 | 47 | 12.5 | 59 | 7.3 | 20.2 | 4.55 | 22.5 | 0.445 | |

| DN25 | 1” | 34 | 34.5 | 47 | 12.5 | 59 | 6.3 | 25.9 | 4. 55 | 22.5 | 0.445 |

| DN32 | 38 | 38. 5 | 55.5 | 12.5 | 69 | 8.5 | 25.9 | 4.85 | 27 | 0.67 | |

| DN32 | 1 1/4” | 42 | 42.8 | 55.5 | 12.5 | 69 | 6.4 | 34. 3 | 4.85 | 27 | 0.67 |

| DN40 | 45 | 45.5 | 62.5 | 12.5 | 76.5 | 8.5 | 34. 3 | 5.08 | 32 | 0.87 | |

| DN40 | 1 1/2” | 48 | 48.9 | 62.5 | 12.5 | 76.5 | 6.8 | 40.1 | 5.08 | 32 | 0.87 |

| DN50 | 57 | 57.5 | 76 | 16 | 89.5 | 9.3 | 40.1 | 5. 54 | 38 | 1.4 | |

| DN50 | 2” | 60 | 61 | 76 | 16 | 89.5 | 7.5 | 51.7 | 5. 54 | 38 | 1.4 |

| DN65 | 2-1/2” | 76 | 77 | 92 | 16 | 103 | 7.5 | 51. 7 | 7.01 | 41 | 2.2 |

| DN80 | 3” | 89 | 90 | 109 | 16 | 128 | 9.5 | 61.2 | 7.62 | 57 | 4.5 |

| DN100 | 108 | 109 | 138 | 19 | 154 | 14.5 | 76.4 | 8.56 | 66.5 | 9 | |

| DN100 | 4” | 114 | 115 | 138 | 19 | 154 | 11. 5 | 100.7 | 8. 56 | 66.5 | 9 |

Parameter

| Forged Steel Fittings Specification | ||||||

| Size | 1/8〞(DN6)to 4〞(DN100) | |||||

| Class | 3000LBS,6000LBS, 9000LBS. | |||||

| Connection Form | Socket Welding/Threaded | |||||

| Surface Treatment | Sand Blasting,Cold and Hot Dip Galvanized | |||||

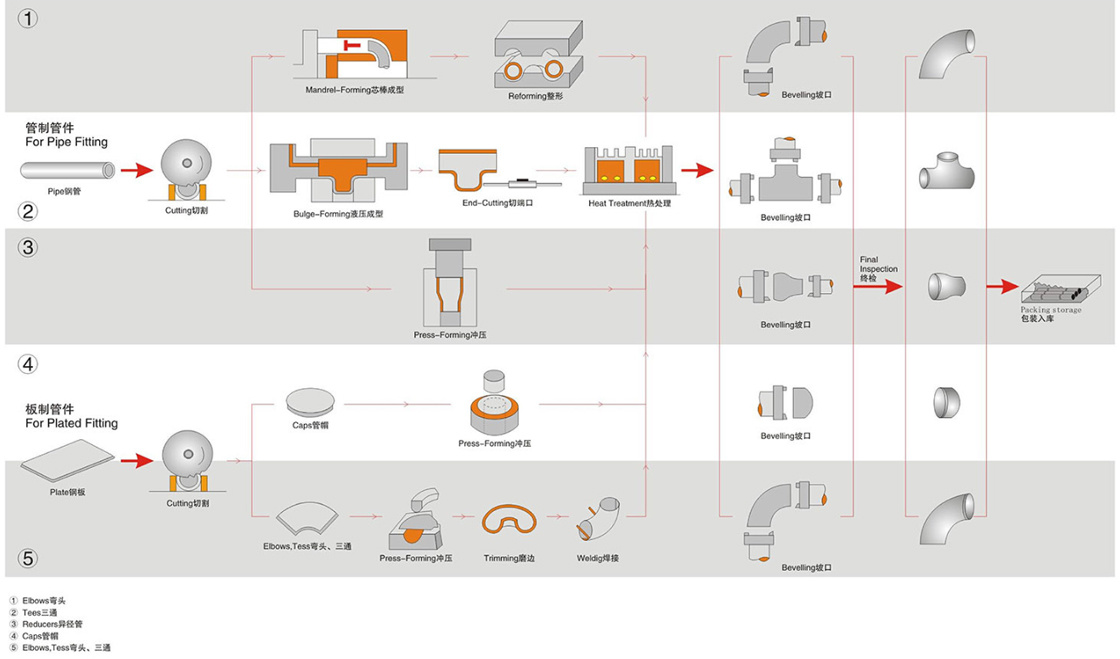

| Manufacturing process | Cutting,Heat treatment,Die Forging/Free Forging,CNC Machining | |||||

| Manufacturing Standards | ASME B16.11,BS 3799,JIS B2316,GB/T14383,SH3410,HG/T21634 | |||||

| Material Grades | ||||||

| Carbon Steel | ASTM/ASNE A105,ASME A350 LF2 LF6 20#,Q235,Q345 | |||||

| Stainless Steel | ASTM F304,F304L,F316,F316L | |||||

| Duplex & Super Duplex Steel | ASTM A182-F51,F53,F55,S31803,S22253,S32205,S22053 | |||||

| Alloy Steel | ASTM F5,F9,F11,F22,F91 | |||||

| Copper Alloy Steel | ASTM/ASME SB466 UNS NO.C70600(CU/NI-90/10),C71500(CU/NI-70/30) | |||||

| Nickel Alloy | ASTM/ASME SB336,ASME SB564/160/163/472,UNS2200(NICKEL200)UNS2201(NICKEL201),UNS4400(MONEL400),UNS8020(ALLOY20/20 CB3),UNS8825 INCONEL(825),UNS6600(INCONEL600),UNS6601(INCONEL601),UNS6625(INCONEL625),UNS10276(HASTELLOY C276) | |||||

Process introduction

About delivery