Stainless steel high pressure 45° socket welding elbow

- Commodity name: Stainless steel high pressure 45° socket welding elbow

Product Introduction

The stainless steel high pressure 45° socket welding elbow is a critical component in many industrial applications where high pressure and corrosion resistance are required. This type of elbow is specifically designed to withstand the harsh conditions of high pressure systems, making it an essential part of pipelines, oil and gas industries, chemical processing plants, and many other industries.

One of the key advantages of the stainless steel high pressure 45° socket welding elbow is its durability and longevity. Made from high quality stainless steel, this elbow is able to resist corrosion and erosion caused by the high pressure and harsh chemicals that flow through the system. This ensures a longer service life and reduces the need for frequent replacements, saving both time and money for the operators.

In addition to its durability, the 45° angle of the elbow allows for smooth and efficient flow of fluids through the pipeline. This reduces the risk of pressure drops, turbulence, and blockages in the system, ensuring a consistent and reliable performance. The socket welding feature also provides a secure and leak-proof connection, further enhancing the efficiency and safety of the system.

Overall, the stainless steel high pressure 45° socket welding elbow is an indispensable component for industries that require high pressure and corrosion resistance. Its robust construction, durability, and efficient design make it a valuable asset in ensuring the smooth operation of industrial systems.

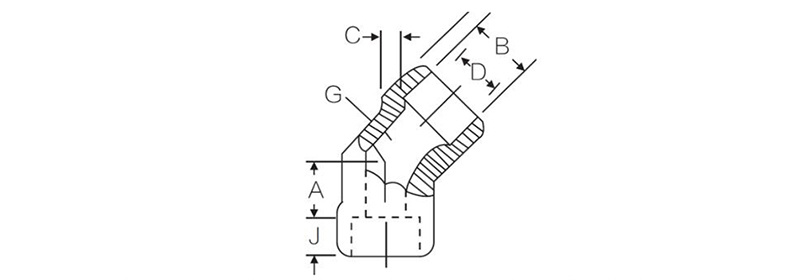

| Specification | Specification | Outside diameter | Socket inside diameter B | Jack depth J | Body wall thickness G | Through hole bore D | Center to socket bottom A | Wall Thickness C | Weight (KG) |

| DN6 | 1/8” | 25 | 10.5 | 9.5 | 2.41 | 6.1 | 11 | 3.18 | 0.1 |

| DN8 | 1/4” | 25 | 14.5 | 9.5 | 3.02 | 8.5 | 11 | 3.78 | 0.1 |

| DN10 | 3/8” | 25 | 18.5 | 9.5 | 3.2 | 11.8 | 13.5 | 4.01 | 0.1 |

| DN15 | 1/2” | 33 | 22.5 | 9.5 | 3.72 | 15 | 15.5 | 4.67 | 0.2 |

| DN20 | 3/4” | 39 | 27.5 | 12.5 | 3.91 | 20.2 | 19 | 4.9 | 0.27 |

| DN25 | 1” | 47 | 34.5 | 12.5 | 4.55 | 25.9 | 22.5 | 5.69 | 0.41 |

| DN32 | 1 1/4” | 55.5 | 42.8 | 12.5 | 4.85 | 34.3 | 27 | 6.07 | 0.68 |

| DN40 | 1 1/2” | 62.5 | 48.8 | 12.5 | 5.08 | 40.1 | 32 | 6.35 | 0.82 |

| DN50 | 2” | 76 | 60.8 | 16 | 5.54 | 51.7 | 38 | 6.93 | 1.41 |

| DN65 | 2-1/2” | 92 | 77 | 16 | 7.01 | 61.2 | 41 | 8.76 | 2.6 |

| DN80 | 3” | 109 | 90.5 | 16 | 7.62 | 76.4 | 57 | 9.52 | 4.23 |

| DN100 | 4” | 138 | 115 | 19 | 8.56 | 100.7 | 66.5 | 10.69 | 8.96 |

Parameter

| Forged Steel Fittings Specification | ||||||

| Size | 1/8〞(DN6)to 4〞(DN100) | |||||

| Class | 3000LBS,6000LBS, 9000LBS. | |||||

| Connection Form | Socket Welding/Threaded | |||||

| Surface Treatment | Sand Blasting,Cold and Hot Dip Galvanized | |||||

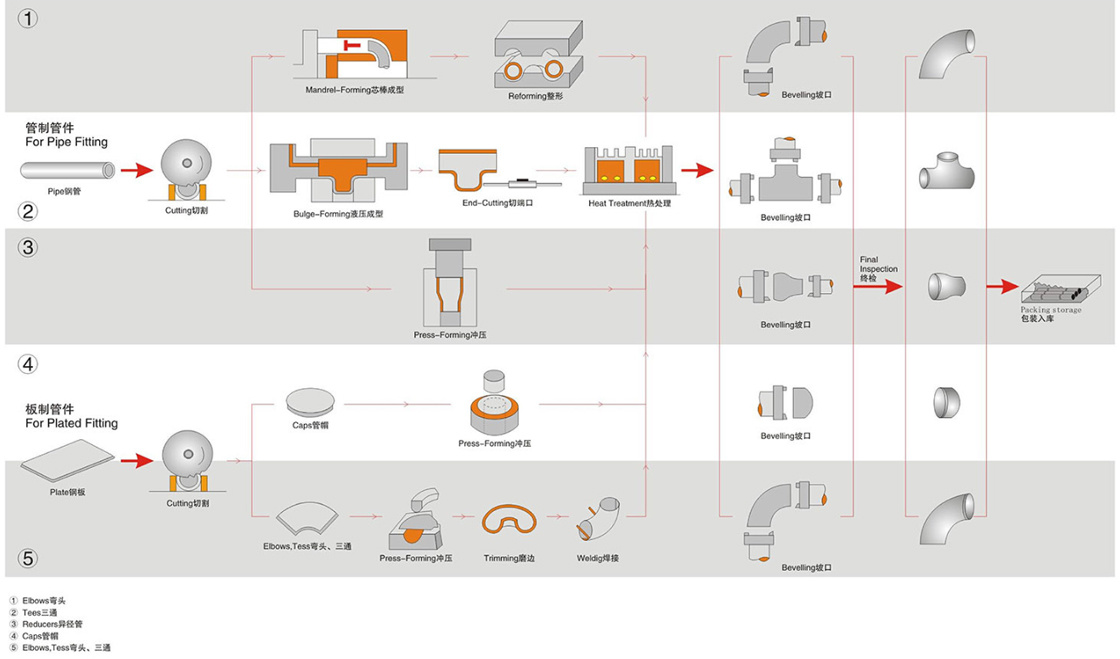

| Manufacturing process | Cutting,Heat treatment,Die Forging/Free Forging,CNC Machining | |||||

| Manufacturing Standards | ASME B16.11,BS 3799,JIS B2316,GB/T14383,SH3410,HG/T21634 | |||||

| Material Grades | ||||||

| Carbon Steel | ASTM/ASNE A105,ASME A350 LF2 LF6 20#,Q235,Q345 | |||||

| Stainless Steel | ASTM F304,F304L,F316,F316L | |||||

| Duplex & Super Duplex Steel | ASTM A182-F51,F53,F55,S31803,S22253,S32205,S22053 | |||||

| Alloy Steel | ASTM F5,F9,F11,F22,F91 | |||||

| Copper Alloy Steel | ASTM/ASME SB466 UNS NO.C70600(CU/NI-90/10),C71500(CU/NI-70/30) | |||||

| Nickel Alloy | ASTM/ASME SB336,ASME SB564/160/163/472,UNS2200(NICKEL200)UNS2201(NICKEL201),UNS4400(MONEL400),UNS8020(ALLOY20/20 CB3),UNS8825 INCONEL(825),UNS6600(INCONEL600),UNS6601(INCONEL601),UNS6625(INCONEL625),UNS10276(HASTELLOY C276) | |||||

Process introduction

About delivery