Carbon steel socket welded branch pipe platform

Carbon steel socket welded branch pipe platform

- Commodity name: Carbon steel socket welded branch pipe platform

Product Introduction

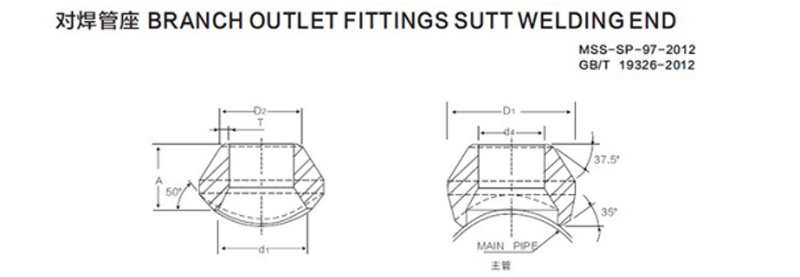

| Nominal diameter of branch pipe | Applicable main pipe nominal size | A | d1 | D1 | D2 | T | d4 | ||

| 6 | 1/8 | 20 | 3/4 | 15.7 | 15.9 | 24 | 10.3 | 1.73 | 6.8 |

| 8 | 1/4 | 20 | 3/4 | 15.7 | 15.9 | 26 | 13.7 | 2.24 | 9.2 |

| 10 | 3/8 | 25 | 1 | 19.1 | 19.1 | 30 | 17.1 | 2.31 | 12.5 |

| 15 | 1/2 | 32 | 1 1/4 | 19.1 | 23.8 | 36 | 21.3 | 2.77 | 15.8 |

| 20 | 3/4 | 40 | 1 1/2 | 22.4 | 30.2 | 43 | 26.7 | 2.87 | 21.0 |

| 25 | 1 | 40 | 1 1/2 | 26.9 | 36.5 | 55 | 33.4 | 3.38 | 26.6 |

| 32 | 1 1/4 | 65 | 2 1/2 | 31.8 | 44.5 | 66 | 42.2 | 3.56 | 35.1 |

| 40 | 1 1/2 | 65 | 2 1/2 | 33.3 | 50.8 | 74 | 48.3 | 3.68 | 40.9 |

| 50 | 2 | 80 | 3 | 38.1 | 65.1 | 90 | 60.3 | 3.91 | 52.5 |

| 60 | 2 1/2 | 100 | 4 | 41.1 | 76.2 | 104 | 73.0 | 5.16 | 62.7 |

| 80 | 3 | 125 | 5 | 44.5 | 93.7 | 124 | 88.9 | 5.49 | 77.9 |

| 90 | 3 1/2 | 150 | 6 | 47.8 | 101.6 | 138 | 101.6 | 5.74 | 90.1 |

| 100 | 4 | 150 | 6 | 50.8 | 120.7 | 154 | 114.3 | 6.02 | 102.3 |

| 125 | 5 | 200 | 8 | 57.2 | 141.3 | 187 | 141.3 | 6.55 | 128.2 |

| 150 | 6 | 200 | 8 | 60.5 | 169.9 | 213 | 168.3 | 7.11 | 154.1 |

| 200 | 8 | 250 | 10 | 69.9 | 220.7 | 265 | 219.1 | 8.18 | 202.7 |

| 250 | 10 | 300 | 12 | 77.7 | 274.6 | 323 | 273.0 | 9.27 | 254.5 |

| 300 | 12 | 350 | 14 | 85.9 | 325.4 | 379 | 323.8 | 9.53 | 304.7 |

| 350 | 14 | 400 | 16 | 88.9 | 357.2 | 411 | 355.6 | 9.53 | 336.5 |

| 400 | 16 | 450 | 18 | 93.7 | 408.0 | 465 | 406.4 | 9.53 | 387.3 |

| 450 | 18 | 500 | 20 | 96.8 | 458.8 | 522 | 457.0 | 9.53 | 437.9 |

| 500 | 20 | 600 | 24 | 101.6 | 508.8 | 573 | 508.0 | 9.53 | 488.9 |

| 600 | 24 | 650 | 26 | 115.8 | 614.4 | 690 | 610.0 | 9.53 | 590.9 |

Parameter

| Forged Steel Fittings Specification | ||||||

| Size | 1/8〞(DN6)to 4〞(DN100) | |||||

| Class | 3000LBS,6000LBS, 9000LBS. | |||||

| Connection Form | Socket Welding/Threaded | |||||

| Surface Treatment | Sand Blasting,Cold and Hot Dip Galvanized | |||||

| Manufacturing process | Cutting,Heat treatment,Die Forging/Free Forging,CNC Machining | |||||

| Manufacturing Standards | ASME B16.11,BS 3799,JIS B2316,GB/T14383,SH3410,HG/T21634 | |||||

| Material Grades | ||||||

| Carbon Steel | ASTM/ASNE A105,ASME A350 LF2 LF6 20#,Q235,Q345 | |||||

| Stainless Steel | ASTM F304,F304L,F316,F316L | |||||

| Duplex & Super Duplex Steel | ASTM A182-F51,F53,F55,S31803,S22253,S32205,S22053 | |||||

| Alloy Steel | ASTM F5,F9,F11,F22,F91 | |||||

| Copper Alloy Steel | ASTM/ASME SB466 UNS NO.C70600(CU/NI-90/10),C71500(CU/NI-70/30) | |||||

| Nickel Alloy | ASTM/ASME SB336,ASME SB564/160/163/472,UNS2200(NICKEL200)UNS2201(NICKEL201),UNS4400(MONEL400),UNS8020(ALLOY20/20 CB3),UNS8825 INCONEL(825),UNS6600(INCONEL600),UNS6601(INCONEL601),UNS6625(INCONEL625),UNS10276(HASTELLOY C276) | |||||

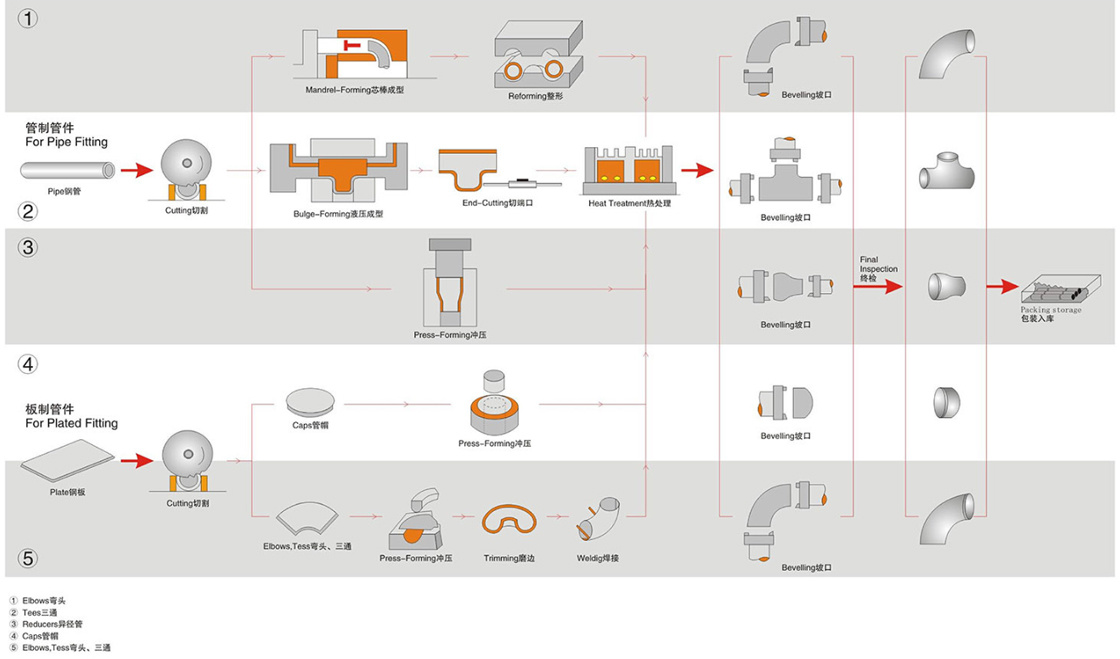

Process introduction

About delivery

Key words: